Products

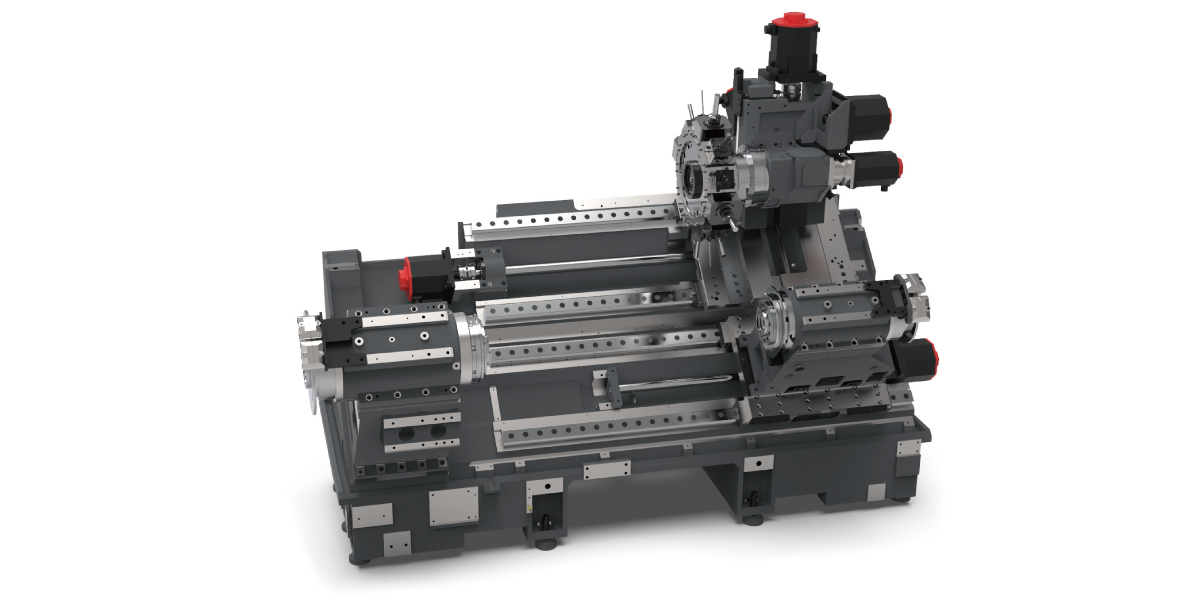

Multi Task CNC Lathe with single turret and Y axis ACUFLEX 400S

Multi Task CNC Lathe with single turret and Y axis provided by Fuji ACUFLEX 400S

This can machine large workpieces with its small appearance.

Advantages of ACUFLEX 400S

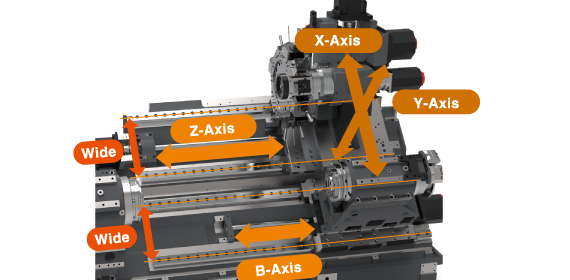

By using a roller guide with a wide mounting pitch for the Z-axis slide and by using boxway slides for the XY axes, both high rigidity and speed are achieved.

In addition, optimum positioning of units and covers achieves a world class workpiece swing diameter.

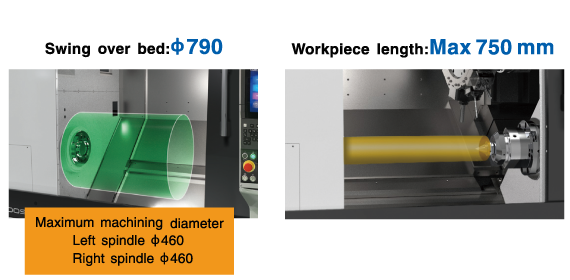

World class workpiece swing diameter

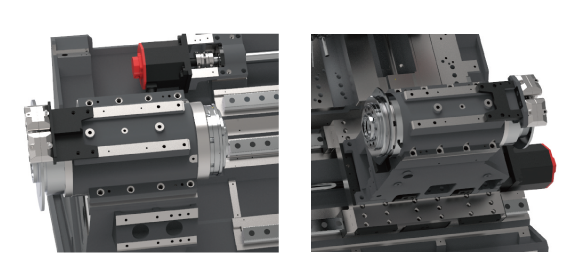

Up to a 15 inch chuck can be mounted on the left spindle.

The space inside the machine is made large as much as possible in order to make the swing large, and large workpieces can be handled.

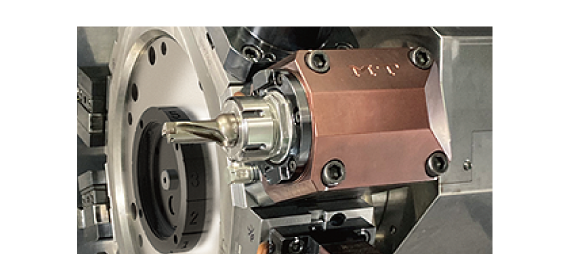

Right spindle equivalent to the left spindle that allows heavy cutting

Roller guides are used for the Z-axis slide and B-axis slide with a wide mounting pitch

Highly rigid boxway slides are used for the X axis and Y axis close to the machining point

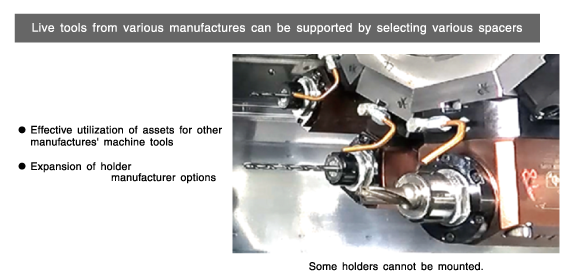

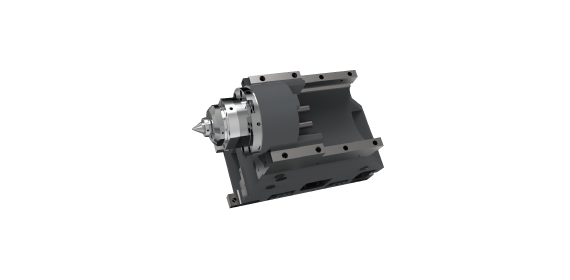

BMT style live tool holders from various manufactures can be attached.

Multitasking allows selection according to intended use such as highly rigid live tools and maximizing the protrusion.

Availability of multifunctional live tools has been increased.

ACUFLEX 400S features

Spindle

・Left spindle : Standard φ120 mm (Option φ100 mm)

・Right spindle : Option φ100 mm

Tailstock (Option)

・Drive system : Servo motor

・Tapered hole shape : Built-in center: MT.4

・Stroke : 830mm

・Maximum thrust : 6,600N

Turret

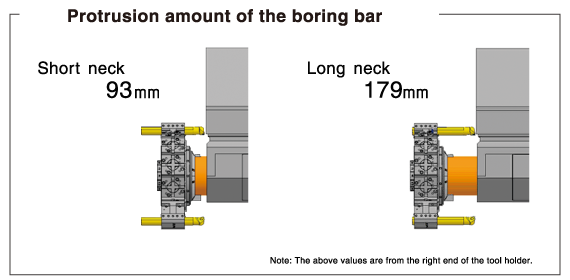

It is possible to select from the following two types: a highly rigid short neck and a long neck with flexibility for right spindle tooling.

A 12 station turret is the standard specifications.The 20 station turret specifications will be added in the future.

Live tool

Highly available BMTs are used.

BMT45 to BMT60 can be used (Standard: BMT55)

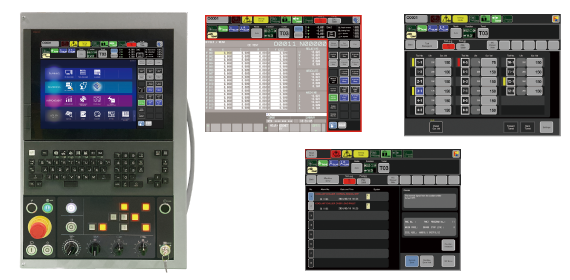

Large operation panel

Usability has been improved by placing a full keyboard in the center of the operation panel.

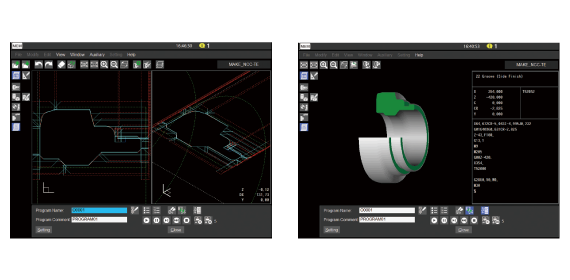

Interactive programming software

・Easy programming by simply creating the shape of the material and workpiece

・Various methods for creating the shape (symbolic input, CAD data input, CAD drawing)

・Possible to create programs for multi task processing (turning, drilling, milling)

・Supports the two spindle machine configuration

・Reduces the time for creating programs by automatically determining processes