sFAB-D Tool Kit for Flexible Handling of New Parts

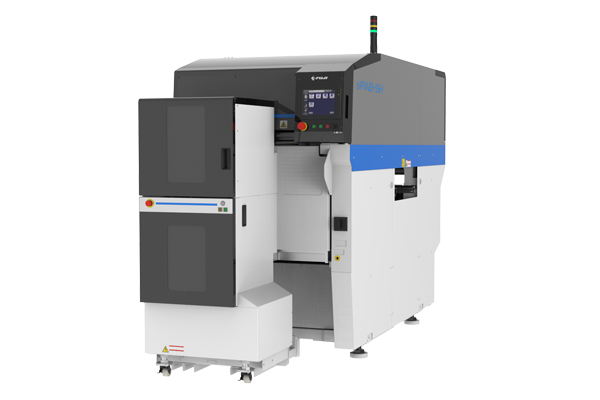

sFAB-D, the multi-purpose automated fabrication machine, is popular product for users who want to automate insertion processes for odd-form parts.

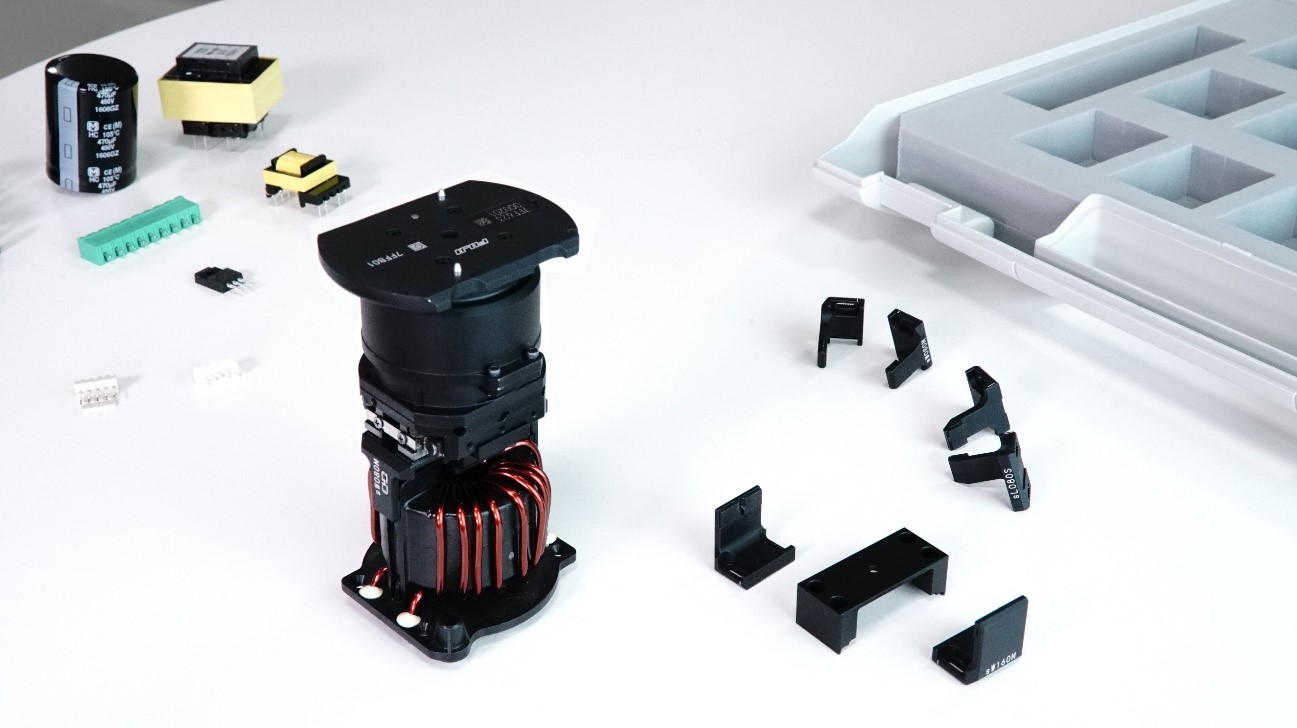

Mechanical chucks that match the shape of the part are required when handling odd-form parts. However, when handling an odd-form part for the first time it can be difficult to work out the positioning reference and clamp position. Because of this, many users may find it difficult when trying to select claws and locators. There is also the issue of the loss in time between ordering a new mechanical chuck and the time it arrives.

To reduce the stress and worry of such events, Fuji has developed claw and locator sets as tool kits for sFAB-D. These tool kits are formulated to include those claws and locators that are most used based on past shipments, to be able to flexibly respond to part additions and changes.

Having these tool kits on hand makes it possible to immediately handle around 80% of odd-form and insertion partsNote, which drastically reduces lead times before new parts can be used in production.

Note: As investigated by Fuji. When using the starter tool kit for light parts and the starter tool kit for small parts.

We strongly suggest looking at using these tool kits for faster startup of production.

sFAB-D tool kit features

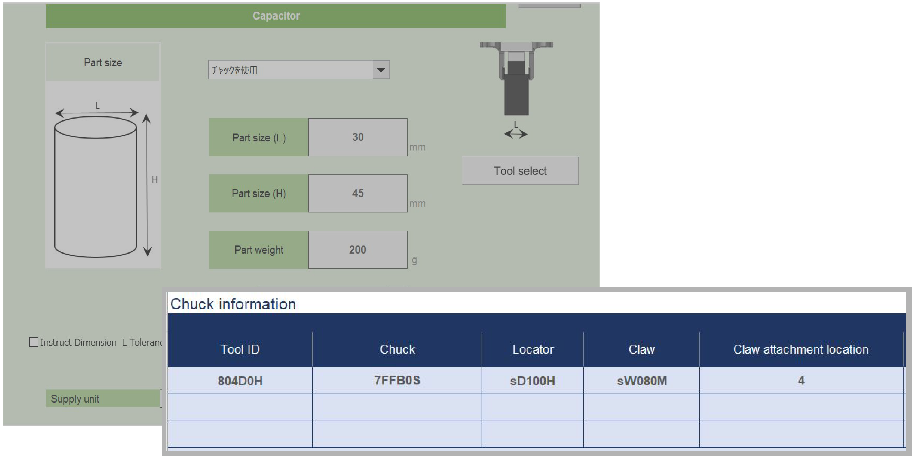

Easy selection of claws and locators

Fuji provides software that lists prospective chuck body, locator, and claw combination candidates just by entering the part size and part weight. This reduces the amount of time trying to figure out the combinations on the tool table, allowing more time for actual testing using the real thing. Also, even if the combination for the chuck is changed while testing using the real thing, it is easy to search for the tool ID from the combination data.

Easy assembly of components

The mechanical chuck body, claws, and locators each have mechanisms for positioning, making it easy for anyone to assemble them together. The ID plate is kept in place using a magnet. By preparing ID plates for highly-used combinations in advance, it is easy to change IDs when changing the assembly.

Easy creation of production data

The data required for production can be created easily just by entering the mechanical chuck body, claw and locator data into the accompanying software.

Data that can be created in the accompanying software

· Spec data for the host system

· Spec data for the machine

· Tool IDs

Basic specifications and compatible units

Basic specifications

| Supported machines | sFAB50, sFAB-D |

|---|---|

| Applicable head(s) | sH02 head |

| Supported part size | Clamp width: 0.5 to 47 mm

Part height: 65 mm or less (including leads) |

| Kit types | 5 types:

· Starter tool kit for light parts · Starter tool kit for small parts · Full set for light parts · Full set for small parts · Full set for large parts |