Reduce the time operators are tied up in changeover work to zero – NXTR PM Smart Changer

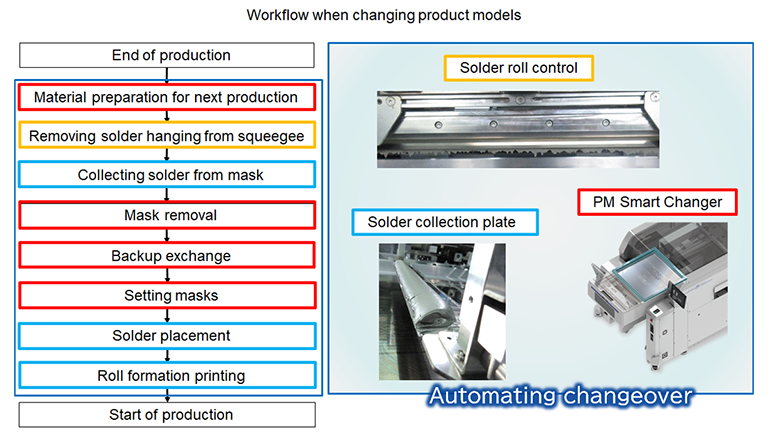

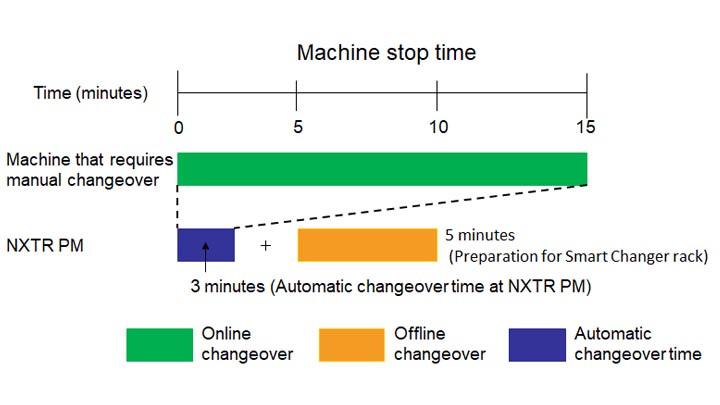

The process of changing product models from the current production to the next production involves a number of manual processes such as solder collection, mask replacement, and replacement of panel backup blocks and backup pins. It takes a lot of time and effort on the part of operators to perform these tasks.

Fuji has already employed automation at its machines in the form of non-stop solder and cleaning paper supply during production, and automatically changing conveyor widths and backup pins. In addition to these, NXTR PM also allows for automatic exchange of screen masks using the PM Smart Changer, making it possible to reduce the time operators are tied up in changeover work to zero.

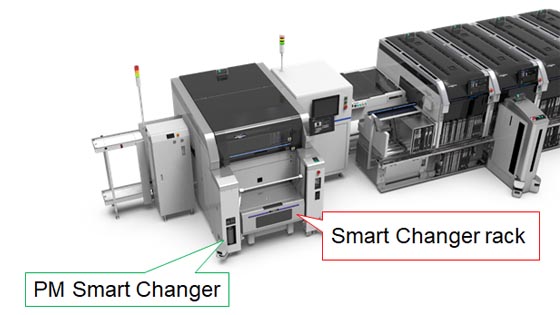

All operators need to do is have the masks and backup blocks needed for next production ready in the Smart Changer rack, which they can do at a time of their own choosing, and load the Smart Changer rack into the NXTR PM.

When a command to change product models is issued from the upper system, solder collection, mask exchange, backup block and backup pin change, conveyor width change, and solder supply are all performed automatically.

Workflow for automatic changeover

1. Have screen masks ready in the Smart Changer rack, and then load the Smart Changer rack into the NXTR PM

2. Screen masks are exchanged automatically during changeover

3. The Smart Changer rack can be collected at the operator's convenience

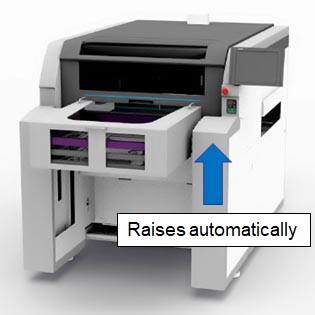

1. Have screen masks ready in the Smart Changer rack, and then load the Smart Changer rack into the NXTR PM

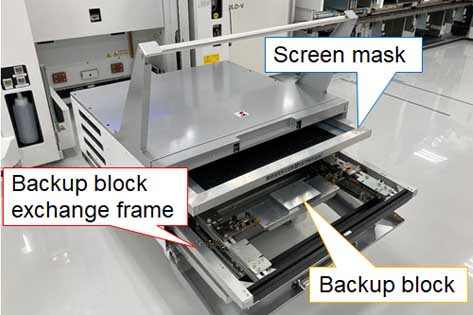

Have screen masks and backup blocks ready in advance in the Smart Changer rack, and then load the rack into the changeover unit. In the future, it will become possible to automate the material delivery process through use of an autonomous mobile robot (AMR) ※1 which will further increase automation of work.

*1: Delivery using an AMR is currently under development

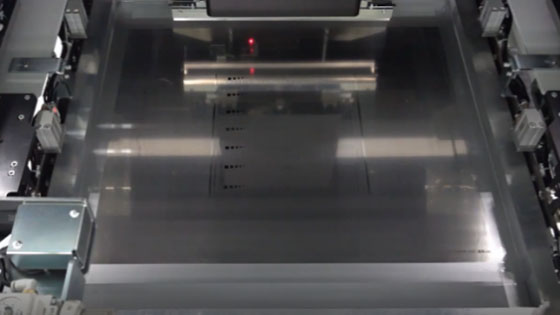

2. Screen masks are exchanged automatically during changeover

The Smart Changer rack is raised to the exchange position when a command to change product models is issued, and changeover is performed. Because screen masks, backup pins, and backup blocks can be exchanged automatically on the NXTR PM, it is possible to automate the entire changeover process. Once exchange is completed, the Smart Changer rack returns to the retract position, and changeover is complete. One exchange process takes approximately 3 minutes to complete.

3. The Smart Changer rack can be collected at the operator's convenience

The Smart Changer rack can be collected from the NXTR PM and loaded with the screen mask required for the next production. Because preparation for next production is done at the operator's convenience while current production is being performed, the corresponding reduction of machine stop time leads to better operation rates and less man-hours required.

Reduce operator workloads with NXTR PM

We hope this has been a satisfactory introduction to PM Smart Changer.

The load on operators has been increasing in recent years with an increase in changeover frequency due to the trend toward high-mix, low-volume production and the need for one operator to oversee multiple machines at once, such as the printer and pick and place machines. In light of this, there have been calls for solutions to the excessive loads placed on operators and the mistakes that occur because of these loads.

Through the automation Fuji delivers with the NXTR PM and PM Smart Changer, all changeover processes can be automated, reducing task loads on operators and removing the risk of human error.

The NXTR PM is also equipped with functions useful for production, such as a traceability function that shows when and at what timing masks, panel backup, and other such materials were exchanged, as well as which materials were used, and a printing support system that enables printing under optimal conditions from the very first panel.

If you would like to know more about this product, feel free to contact us.