Products

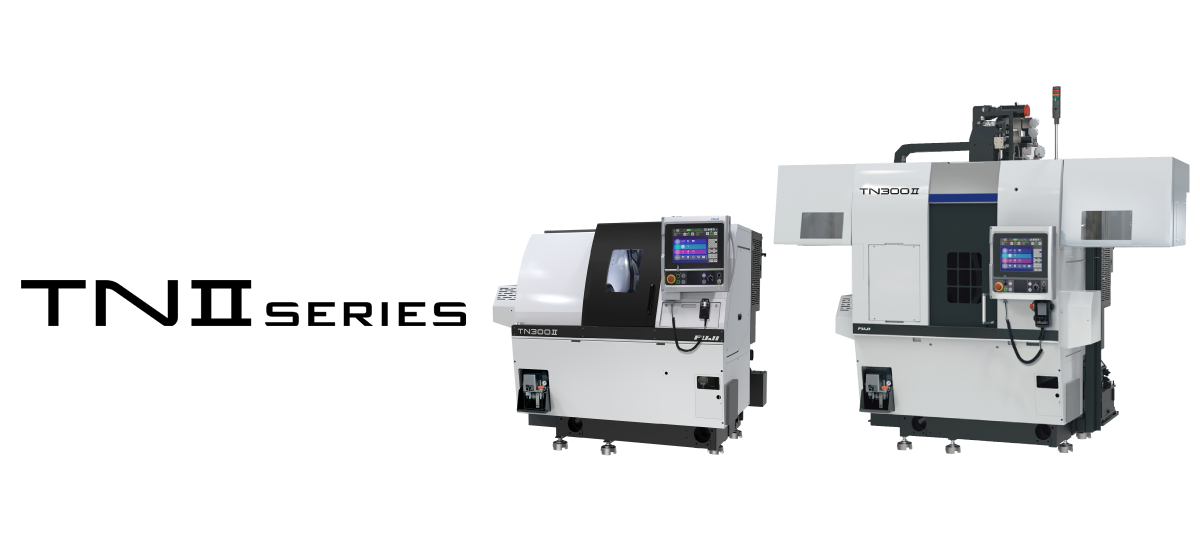

TN II series

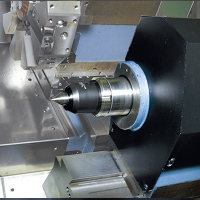

Horizontal CNC Lathe TN II series

This is a standard horizontal NC lathe.

Cost effective lathe with high machining performance and excellent thermal displacement.

Features

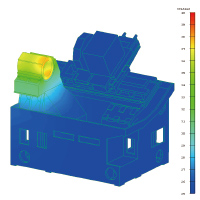

Heat balancing bed

The Fuji engineered bed is designed to be highly rigid while minimizing thermal displacement. In this design, This heat balancing bed uses the feedback from the latest CAE analysis and the actual inspection results to their fullest.

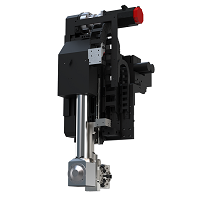

L67II gantry robot

Robot control is integrated with FANUC. Two pieces with a double slide action structure is used on the vertical axis to minimize the height of the machine when the robot rises. The hydraulic hand clamp system is a reliable transport for heavy objects.

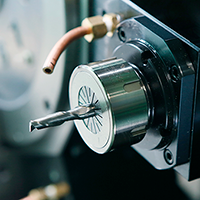

Live tool

Live tool that rotates up to 4000. Note: TN400IIR

Tailstock (option)

Shaft work pieces are supported with the equipped tailstock.

■TN300II

| Quill stroke | 180, 230mm |

|---|---|

| Center type | Live Center MT.4 Built-in type MT.3 |

■TN400II

| Quill stroke | 180, 230mm |

|---|---|

| Center type | Live Center MT.5 Built-in type MT.4 |

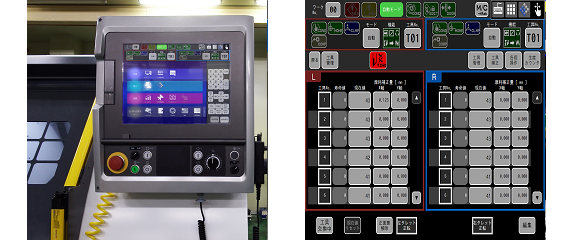

FUJI original operation panel ”Feons”

FUJI original operation screen with improved operability and maintainability.

Intuitive operation is possible by integrating the lamp and button.

Global support by switching between multiple languages.

Equipped with iHMI as standard. Interactive-style programming supports high-mix low-volume production.

Tool Load Monitoring & Broken Tool Detection Function (Option)

This system monitors the spindle motor load and amperage to detect abnormal tool loads during cutting.

Two types of Tool Load Monitoring & Broken Tool Detection Function are available: "ILM Light", For High Accuracy Tool Load & Breakage Detection Monitoring and "SLM", For Simple Tool Load & Breakage Detection Monitoring.

Line up

Manual lathe

This is a standard type in which an operator needs to attach and remove work pieces.

Automatic lathe

Standard lathe with added robot makes automation possible.