Sustainability

Society | Customer relations

Sales activities that meet our customers' needs

We hold regular sales meetings with our group companies and regional agents in the Americas, Europe, and Asia. We share information on priority activities inclusive of issues in each region. This enables us to deepen cooperation among regions in sales activities.

By providing support both face-to-face and online, we strive to always stand by customers and cater to their needs.

Disseminating information through face-to-face and digital interaction

We propose solutions to issues faced by customers through exhibitions held in Japan and overseas, productivity improvement services, and websites. These events allow us to provide information and solutions, as well as to communicate with our customers. When face-to-face communication is difficult, we offer digital interactions such as online demonstrations, seminars, and remote online process diagnostics.

Exhibitions/Private shows by region

Technical seminars by region

Fuji Headquarters Showroom

FUJI KAIZEN Service

Online demonstrations

Global support

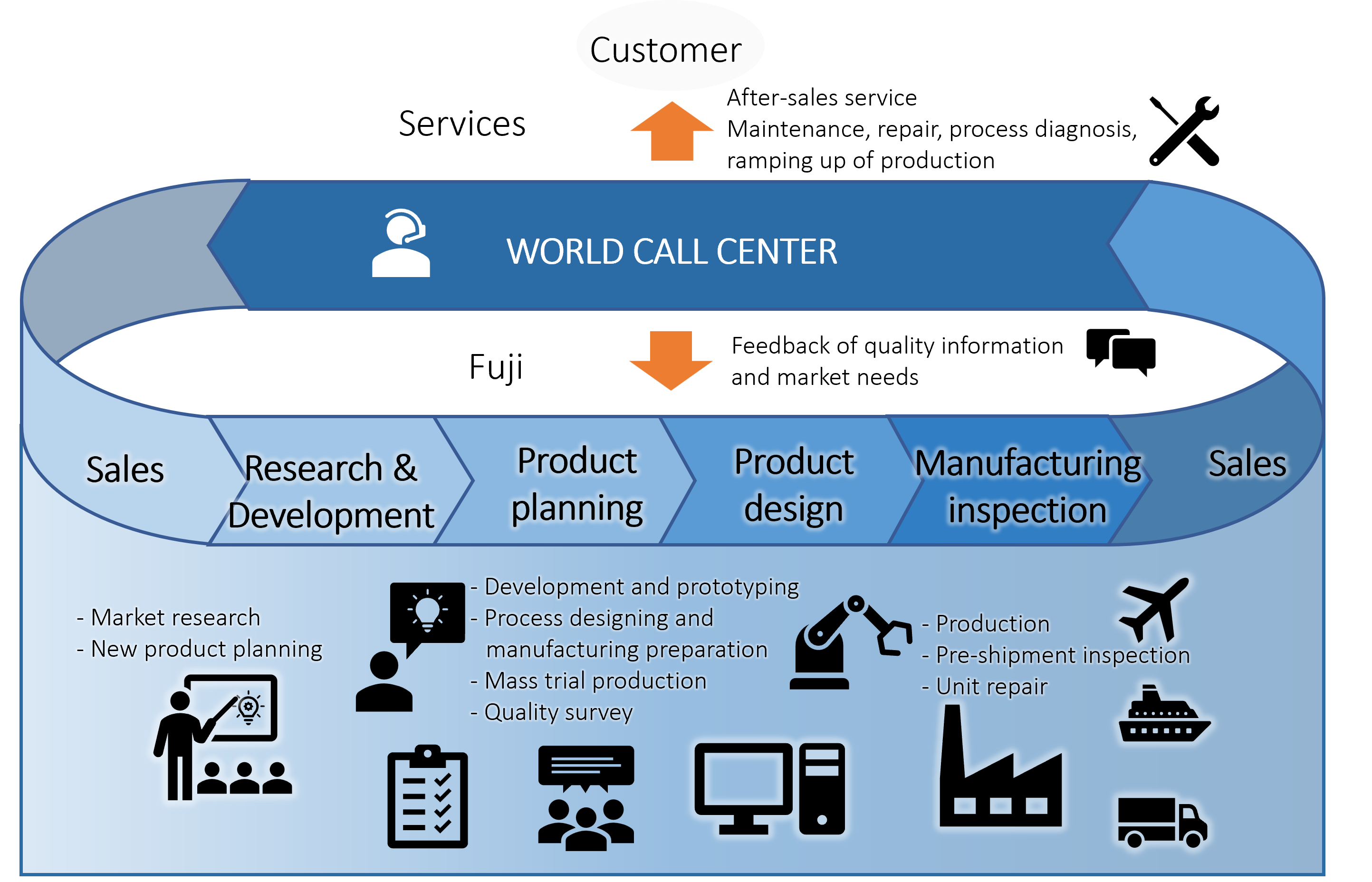

In line with our customer first approach, we engage in after-sales service, maintenance, CS surveys, and checks of production line processes, and customer requests obtained through these activities are fed back to the Company. Checking production line processes helps customers reduce energy consumption by increasing production efficiency and also develops a safer workplace environment through improved production site conditions. With an eye on the feedback from customers, we engage in research and development of advanced technologies and development of products and services that contribute to solving social issues, and link to offering new values to customers.

Our stationed staff and agents' service engineers are engaged in daily customer support at more than 100 locations in Japan and overseas. Customer inquiries are registered in our customer management database and handled by our call center in Japan on a 24-hour schedule in cooperation with service engineers. We analyze information on inquires and parts replacement, and regularly feed customer requests back to our engineering departments in an effort to improve quality on a daily basis.

Basic quality policy

Guiding principles

-

- Establish and implement a quality management system that can keep the trust of customers.

- Seek higher customer satisfaction through continuous improvement of the quality management system.

- Disseminate the importance of our business activities in satisfying legal, regulatory, and customer requirements within the organization.

- Recognize eradication of non-conforming products as a minimum requirement, enhance product development capabilities, and provide products that are as the customer expects in a timely manner.

- Set quality targets to embody the basic quality policy, and disseminate them to all relevant staff for addressing.

- Conduct management reviews and review the appropriateness of the quality targets.

- Establish a forum for communication to ensure the exchange of information, and provide the management resources necessary for the quality management system.

(Revised in July 2013)

Acquired ISO 9001 certificate (quality management systems)

We acquired the ISO 9001 certificate, which is an international standard published by the International Organization for Standardization.

Certification body: Bureau Veritas Japan Co., Ltd

- Certificate No:JP024668

Listed sites in certification: Fuji headquarters, Toyota Plant, Okazaki Plant

Maintaining and improving quality

-

Product development and design

Our corporate message "innovative spirit" underlines our day-to-day engineering and development of new products and solutions. We are constantly working to create new values, aiming to excite and inspire customers.

Our customers are always looking for high quality, high performance, low cost, and short development periods. To meet these expectations, we focus on optimizing costs and development periods, as well as developing unique and competitive products.We are committed to maintaining and improving quality by refining our products and services through enhanced development capabilities and the use of data and AI, with the aim to maximize the return on users' capital investment. We also emphasize environmental innovation based on life cycle assessment and security measures to develop environmentally friendly and people-friendly products. In the development process, we utilize the front-loading approach to shorten development lead time and pursue optimal costs. This enables us to provide products that promptly reflect customer needs, thus leading to increased competitiveness. Through these continuous efforts of improvement, Fuji aims to deepen the trust of customers and continue to provide the best products in the world.

-

Manufacturing

With the basic concept of "not passing non-conforming products to subsequent processes," we are promoting an independent process conclusive approach, where our operations in the production and inspection processes are thoroughly standardized to ensure stable quality. In addition to developing multi-skilled workers, we are working to establish manufacturing processes using digital technologies. Using automated systems and robots allows us to reduce human errors and variations to a minimum for improved quality.

-

Human resource development

We provide two multi-skilled human resource development programs aimed at nurturing human resources with a strong sense of involvement who will lead Fuji to the future. One gives five-year engineers an opportunity to experience machine installation, production ramp-up support, and on-site inspection and repair services, both in Japan or overseas for a period of one year. The other program is designed for leader-level employees who engage in on-site manufacturing to experience the entire process ranging from assembly, adjustment, inspection, shipping, installation, production ramp-up, to the call center. We expect theses programs to help employees foster a strong sense of involvement, driving Fuji to maintain the best quality in the industry. products operating in their factories. Through the global engineer upskilling program, we engage in the training and development of staff who can handle a wide range of tasks from product operations to software support.