Business

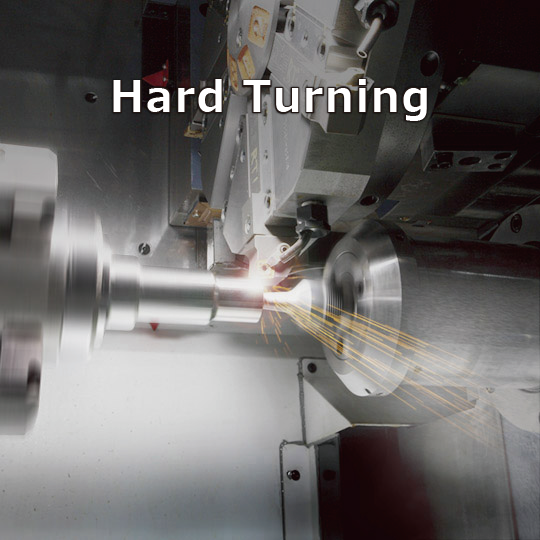

Machine tools | Hard Turning

Hard Turning

The grinding method of hardened high accuracy components for automobile parts assemblies started to transition to NC turning machines about 20 years ago. This was mainly possible due to the improvement in accuracy of NC lathes and the development of CBN Tooling. In the subsequent years, High accuracy hard turning was continuously pursued and realized. Fuji acquired expertise in hard turning through continuous collaboration with cutting tool, automobile, and bearing manufacturers. As a result, Fuji has released a series of high accuracy hard turning lathe machines: FAN31P, VN40P, ANS31P, and PN.

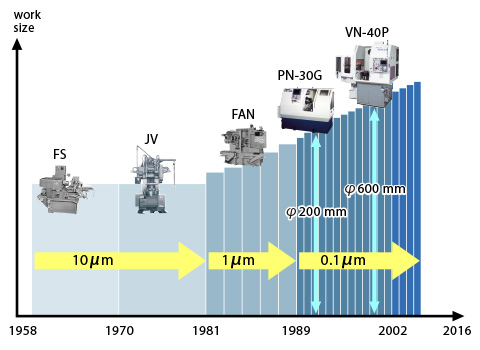

Progression of Fuji Lathes to high-accuracy shape turning.

Fuji was originally established as a manufacturer of hydraulic single-function machines. In the subsequent years, Fuji developed and produced additional lathe machines and pioneered hard turning in the early 1980’s. Current model Fuji lathe machines have evolved with the advancement of technology to achieve submicron-turning accuracy. Today our Research and Development Engineers are working to develop the next generation of larger submicron- high accuracy turning machines for the future.

Advantages of hard turning

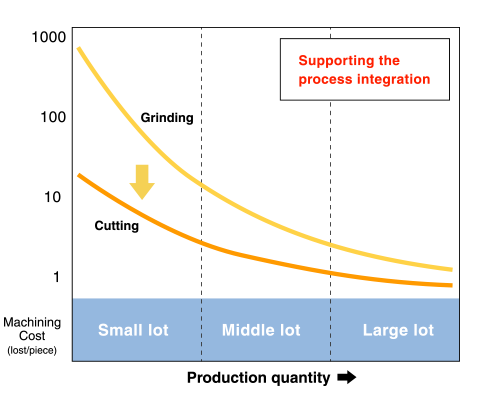

Reduction of facility cost and space

-

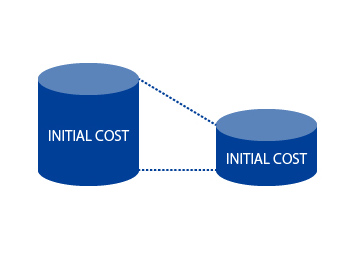

◆Reduction of initial investment

The cost of investment for a lathe is 50% less than that of a grinding machine

-

◆Reduction of energy consumption

The energy consumption of the lathe is 50% less than that of a grinding machine.

-

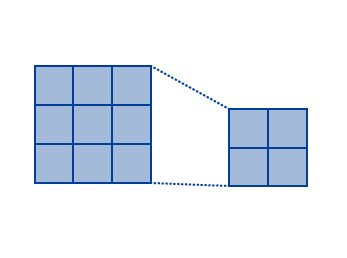

◆Reduction of installation space

The installation space requirement for the lathe is 50% less than that of a grinding machine.

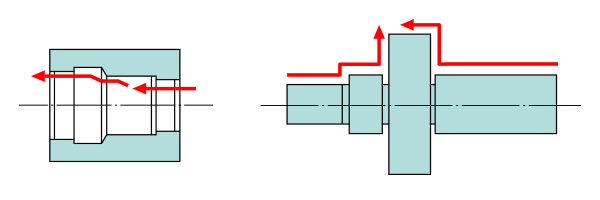

Increased production capability and flexibility

Supports the machining of small diameter complex parts

Reduction of factory waste

Treatment and disposal of sludge or waste liquid with a grinding machine is difficult and is much easier to manage with the turning machine cutting process.

Machining examples for hard turning

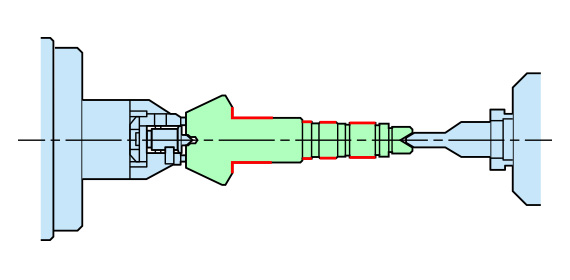

◆Pinion Drive Shaft

Required accuracy: Outer diameter tolerance ±6 µm, outer diameter runout 10 µm

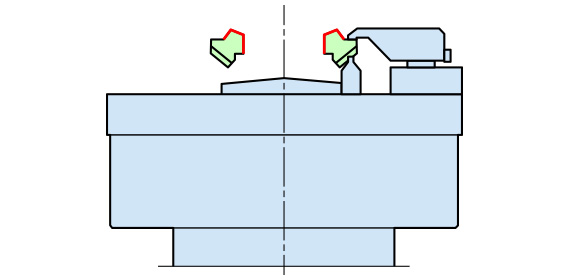

◆Hypoid Gear

Required accuracy: Inner diameter tolerance ±9.5 µm, end face runout 10 µm