Business

SMT Equipment|Improving production processes

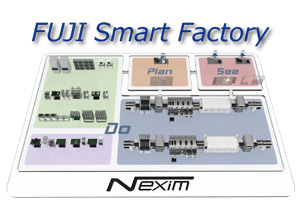

Fuji has developed and provided functions for electronic component mounter robots, automation units for related works, and systems to manage data, aiming to make SMT process-oriented production more efficient.

Making SMT processes more efficient

Changing production sites to be able to handle high-mix production and on-demand production is required in line with changes in consumption based on current trends such as the diversification of needs on a global scale and the proliferation of the Internet.

Fuji, as a manufacturer of panel manufacturing equipment, continues to develop and provide machines, functions, and systems to allow users to perform production flexibly and efficiently through Fuji Smart Factory.

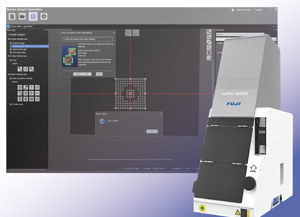

Reduces workloads in creating programs when starting production

Creating part data required for new production requires labor and time.

Automatically creating part data from imported part img can reduce workloads and time. Furthermore, it can bring good results regardless of the skill level of the operator.

Data can be verified during creation to ensure that complete and high quality part data can be made in a short time.

Conditions at the machine can be replicated using a camera stand, so data can be created offline without having to use a machine.

*Data for some parts cannot be created automatically.

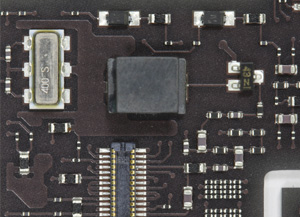

Faster placement of very small parts

Smaller products with higher functionality require high-density placement with small parts for assembling electronic circuit boards. We have achieved industry-leading productivity in placement of very small parts such as 0201 (008004") parts.

Reduces workloads and makes it more efficient

Changeover before production, part supply during production, and equipment maintenance are essential. Fuji provides automation solutions not just for reducing workloads but for providing uniform quality and standard work times. This makes it easier to manage work schedules.

- Improving production processes

- Reduction in work mistakes

- Maintaining quality

- Reduction in time required for changeovers

- Visualization