Business

SMT Equipment|Reduction in time required for changeovers

It takes a long time to change in order to produce a different product. Reducing the changeover time is a very important issue especially for users performing high-mix low-volume production. Fuji allows you to spend more time performing production by reducing the times that changeover is performed and by automating processes to supporting you in both aspects of machines and systems.

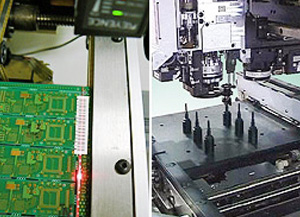

Automates changeover work

Operator work during changeover is greatly reduced by using automatic job changeover, automatic backup pins, and by having shared optimum feeder and nozzle setups.

- Nexim

- Fuji Flexa

- Automatic changeover function

- Auto backup pin function

Reduces changeover times

Especially for high-mix production, the line stop time due to changeover work reduces production time, resulting in lower productivity.

With Nexim, our integrated production system, changeover times can be reduced by grouping parts that have high shared rates for each production. This makes it possible to secure longer production times without having to perform a lot of changeover work during each changeover.

- Nexim

- Scheduler

Automates part preparation

Part preparation is one of the most time-consuming work among changeover work.

sTower II, an automatic part warehouse, can flexibly store not only reel parts but also parts supplied in JEDEC trays, dry packs, and fragile paper tape. It also can store loose parts.

By connecting the sTower II to the Nexim system, it can check out the required quantity of parts when needed according to the production schedules. This greatly reduces the workload for part preparation.

- Improving production processes

- Reduction in work mistakes

- Maintaining quality

- Reduction in time required for changeovers

- Visualization