NEWS

Fuji Innovation Day in Kanazawa and Kobe 2019 event report

Products / Technologies / Exhibitions

Products / Technologies / Exhibitions

We would like to express our gratitude to everyone who took the time out of their busy schedules to join us at Fuji Innovation Day, which was held on December 17 in Kanazawa and on December 20, 2019 in Kobe. And thank you to everyone who helped make these a success.

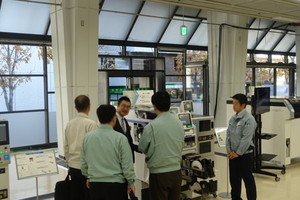

We showcased and demonstrated our latest machines in the exhibition area. We also introduced our placement machine roadmap and latest technology in the technology seminar.

Machines on display

Next Generation Placement Solution

FUJI Smart Factory Platform

NXTR

Aiming for our development concept "three zeros" (zero placement defects, zero machine stops, and zero machine operators), we have made the Smart Loader which makes performing automatic part supply and changeover for the next production without stopping the machine possible.

NXTR PM

A high productivity rate can be maintained because solder can be supplied and cleaning paper can be exchanged during production. The time for ramping up mass production can be drastically reduced by the newly developed printing support system.

Cutting edge placement solutions

NXT III

This is a Fuji Scalable Placement Platform that has the flexibility to meet all types of production conditions from high density placement of very small parts to placing large odd-form parts and to even applying glue just by exchanging and setting units.

H24A head

The head supports soft placement that prevents parts from being left behind when dipping or staying on the nozzle if the part has low tacking force.

H01V head

The air flow has been increased to be approximately six times higher. This makes it possible to stably handle odd-form parts that are difficult to be picked up due to a small pickup surface.

Large odd-form parts placement solutions

AIMEX IIIc

These are all-in-one placement machines that maintain production with high quality and high efficiency by minimizing changeover work that frequently occurs for high-mix production.

DX head glue tool

The glue tools have been added to the lineup of tools for DX heads that are capable of placing parts from 0402 (01005") to large odd-form parts using one head. This glue tool can be used to provisionally secure key parts and prevent defects that occur during reflow such as raised parts.

Assembly process automation solutions

sFAB-D

These are multipurpose fabrication machines that automate various assembly processes from insertion of axial and radial parts to parts supplied in sticks or loosely.

M2M / IoT system solutions

Integrated Production System - Nexim

In addition to the functions of a conventional production management system, this system connects stages and machines as well as centrally managing production related data.

Process/equipment improvement solutions

Demonstrations of automatic maintenance units

These units can automate maintenance (cleaning, inspection) for nozzles, feeders, and heads. History management is also possible by linking with the system. Visitors brought their units to have them cleaned and check the effects at the venue.

Seminar overview

The latest placement machine roadmap

The smart factory roadmap based on trends for placement machines and SMT parts as well as M2M and IoT solutions was introduced.

Mounting process innovation

The next-generation mounting processes that support diversifying and more difficult placement were introduced.

The latest feedback technology through mounter cooperation - OMRON Corporation

OMRON presented the quantitative inspection of solder shapes using 3D-AOI, mounter cooperation using Q-upAuto along with the latest feedback technology. They also introduced examples of process improvements using M2M system with a perspective on quality after the reflow process.

Solder inspection technology that supports high density printing - CKD Corporation

CKD introduced the VP series from their solder printing inspection machines with solutions that support high density placement of increasingly smaller electronics parts.

Solder paste reflow solutions - TAMURA Corporation

As well as introducing their latest machine VP9000 series, TAMURA presented the market trends, relationship of mask apertures and printed solder amount, their engagement in higher inspection accuracy, and their examples of process to process integration regarding the continually accelerating rate of SMT high-density placement.

The latest screen mask technology - Sun Craft Corporation

Printing is essential and the most important factor for placement. Sun Craft introduced the latest trends of technologies with a focus on screen masks for achieving stable printing and placement amid the diversification of placement parts.

Workshops

Fuji and participating companies introduced their latest technologies and products.

Participating companies

Sun Craft Corporation

CKD Corporation

TAMURA Corporation

Hioki E.E. Corporation

The feedback that we received from everyone who came is greatly appreciated. The support that you give us is what allows us to continue to strive toward products and services that exceed expectations. We are looking forward to seeing you next time.