Sustainability

Climate Change : Initiatives

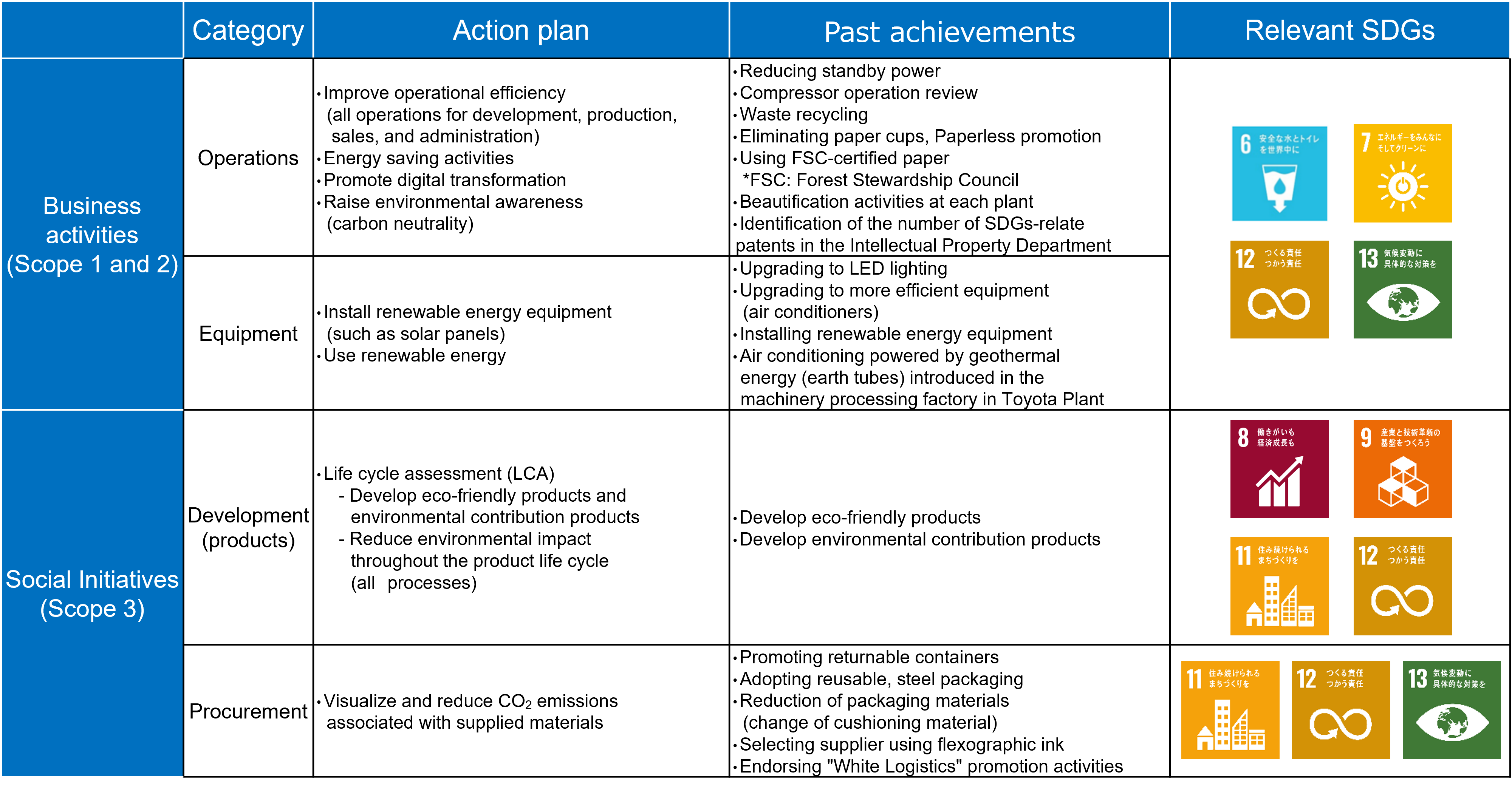

Environmental action plans for fiscal 2025 to 2027 and achievements

We update the environmental action plans every three years, and validate the target values with our performance for the key categories every year.

At the same time, we make it clear which activities are relevant to which goal of the 17 SDGs and implement the PDCA cycle for environmental management practices.

Implementation of internal carbon pricing

The internal carbon pricing (ICP) system was implemented in fiscal year 2026.

An internal carbon pricing of 7000 yen per t-CO₂ was established for CO2 emissions and is reflected in capital investment evaluations and decision making on CO2 emission reduction measures. This year, we have started small in capital investment projects with certain departments, with plans to expand to a group-wide structure in the future.

By not only considering direct costs such as utility bills, but also the costs associated with CO2 emissions that may be incurred in the future, we are able to make more realistic and understanding investment decisions. We are certain that this will further advance our decarbonization efforts.

Renewable energies

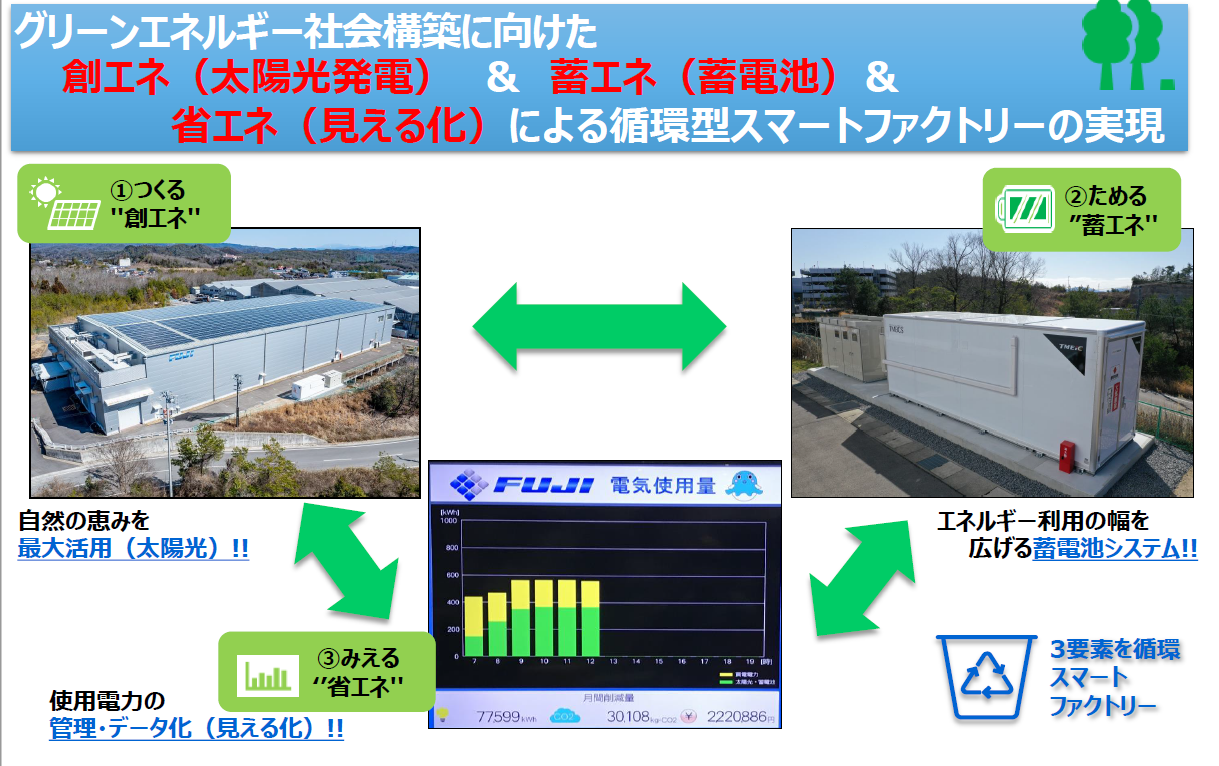

Installing solar power generation systems

In addition to Fuji Toyota Plant's part processing factory, EDEC LINSEY SYSTEM, and Fasford Technology, solar power generation systems have begun operating in some buildings at Fuji Okazaki Plant from September 2024. The annual power generation is 1,594,000 Kwh, which can reduce CO2 emissions by approximately 670 tons per year.

the machinery processing factory in Toyota Plant

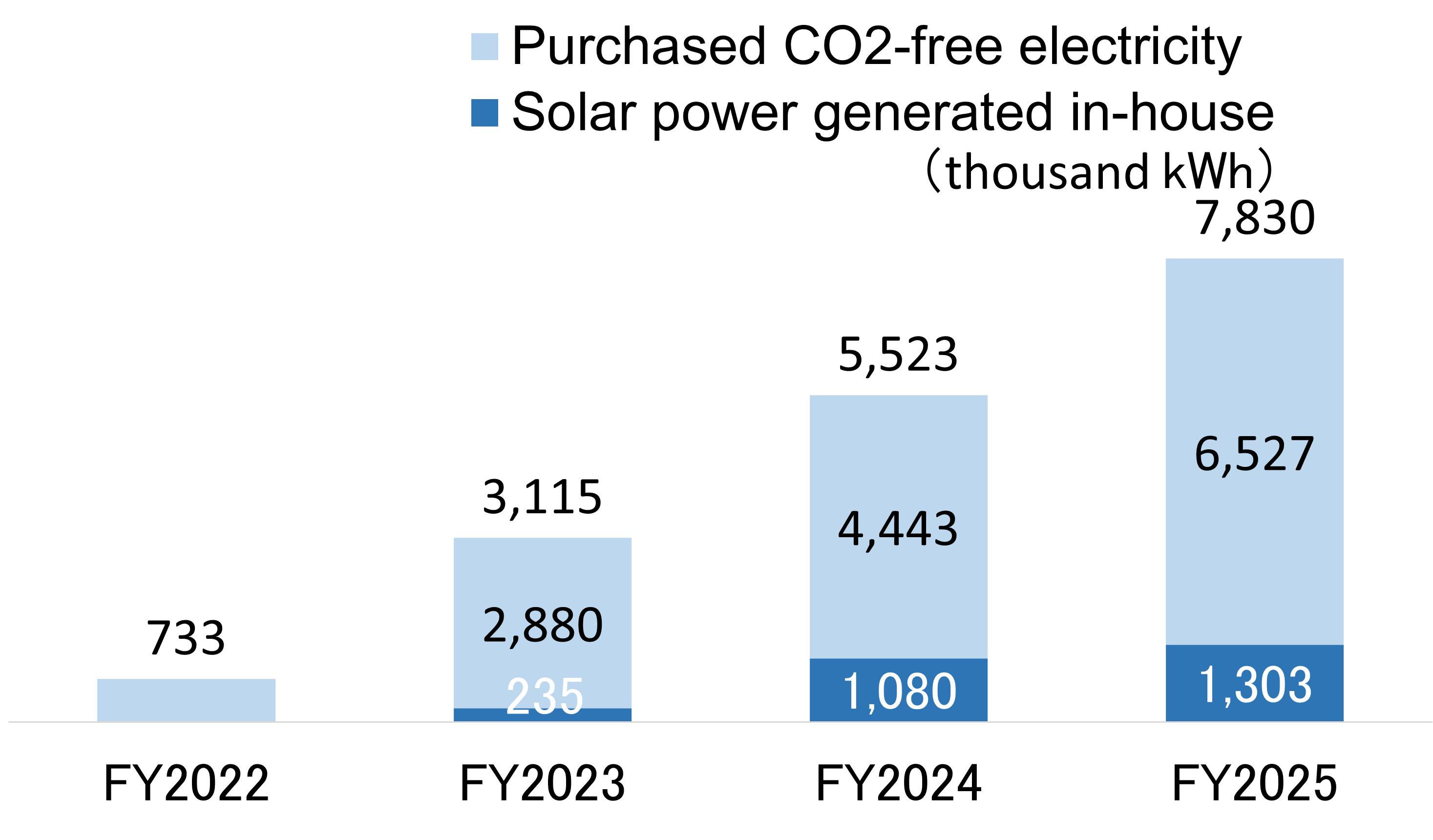

Use of renewable energies

Fuji Group is gradually increasing the ratio of CO₂-free electricity purchased to reduce CO₂ emissions.

ADTEK FUJI has been purchasing CO₂-free electricity only since July 2023, while since October 2022, Fasford Technology has been using electricity generated by the Yamanashi Prefectural Enterprise Bureau's hydroelectric power plants through the prefecture’s hydroelectric power project. We are thereby emitting zero CO₂ emissions from our electricity use.

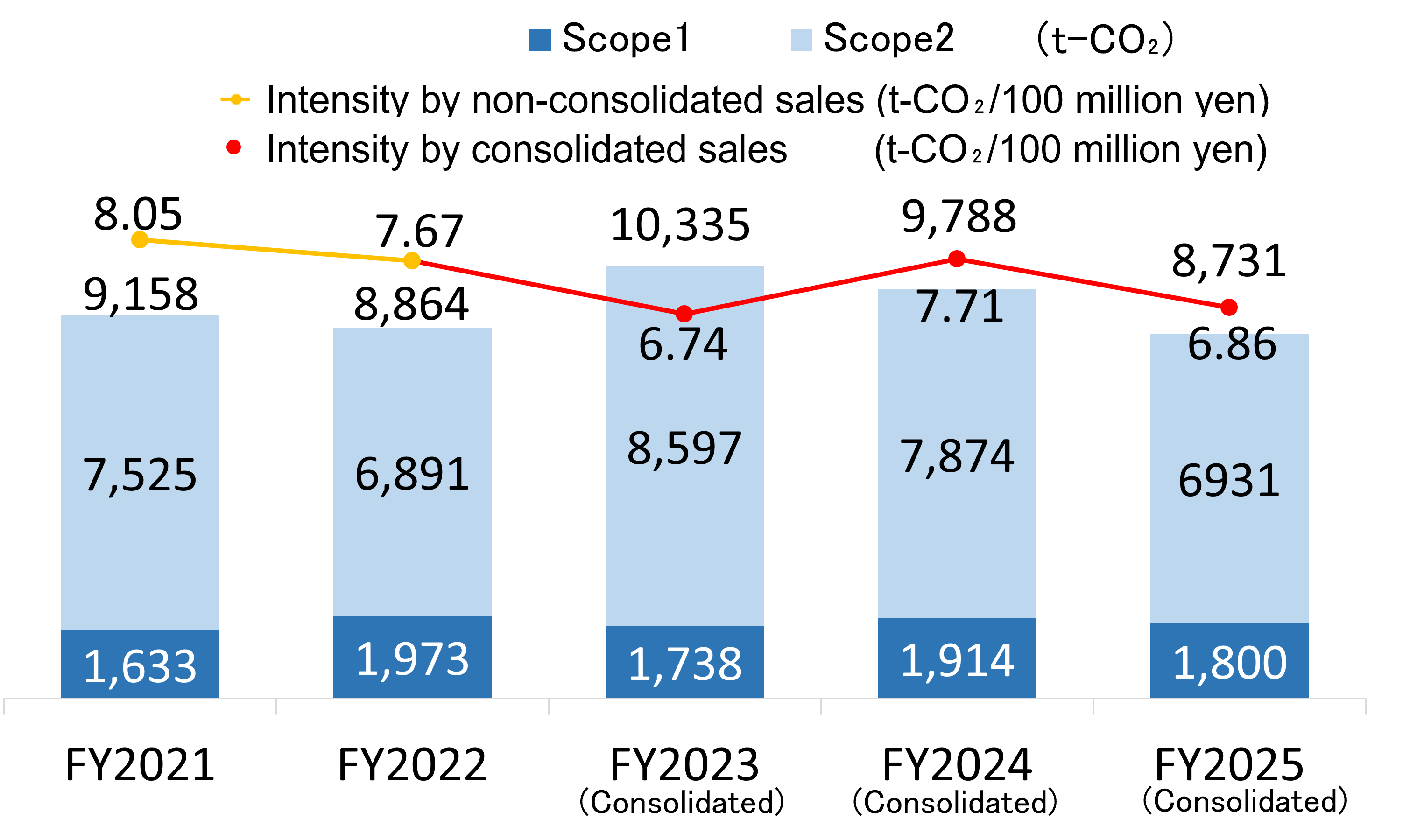

CO₂ emissions and intensity by sales

In addition to energy-saving activities by employees, we are striving to reduce CO₂ emissions through installing energy-saving equipment, purchasing CO₂-free electricity, and managing room temperatures.

Target: To reduce Scope 1 and 2 emissions to 5,476 t-CO₂ in fiscal year 2031.

Amount of renewable energies introduced

In addition to Fuji Toyota Plant's part processing factory, EDEC LINSEY SYSTEM, and Fasford Technology, solar power generation systems have begun operating in some buildings at Fuji Okazaki Plant from September 2024.

Fuji Group is gradually increasing the ratio of CO₂-free electricity purchased to reduce CO₂ emissions.

Target: To achieve 100% renewable energy in electricity use at the headquarters in fiscal year 2026.

Develop eco-friendly products

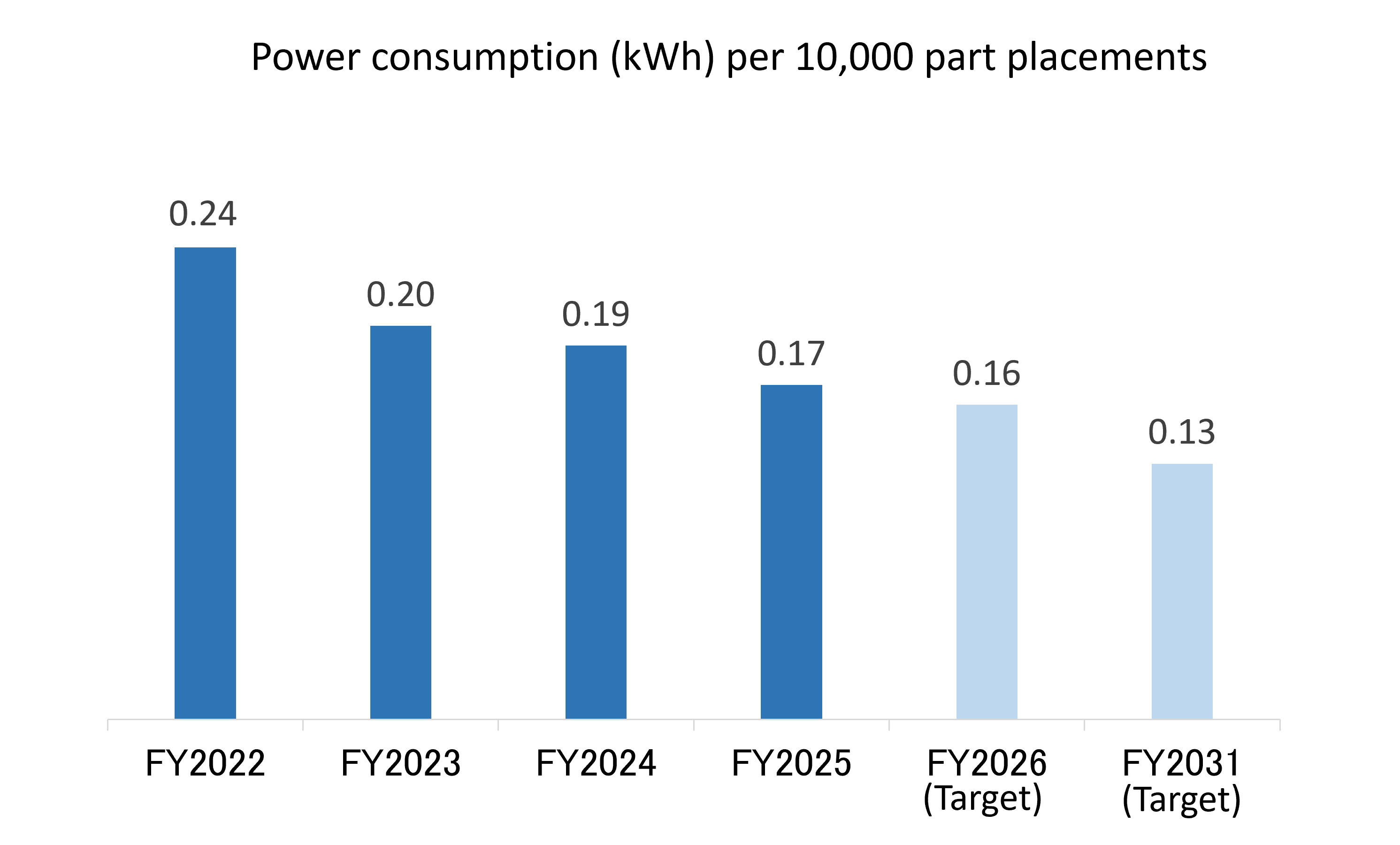

We will promote reduced power consumption by improving the placement speed of the "NXTR" SMT pick and place machine. We are also working to reduce the weight of materials used, recycle materials, reduce consumables used during electronic part placement, and curb air consumption to reduce loads that impact the product life cycle. NXTR is capable of mounting 120,000 parts per hour.

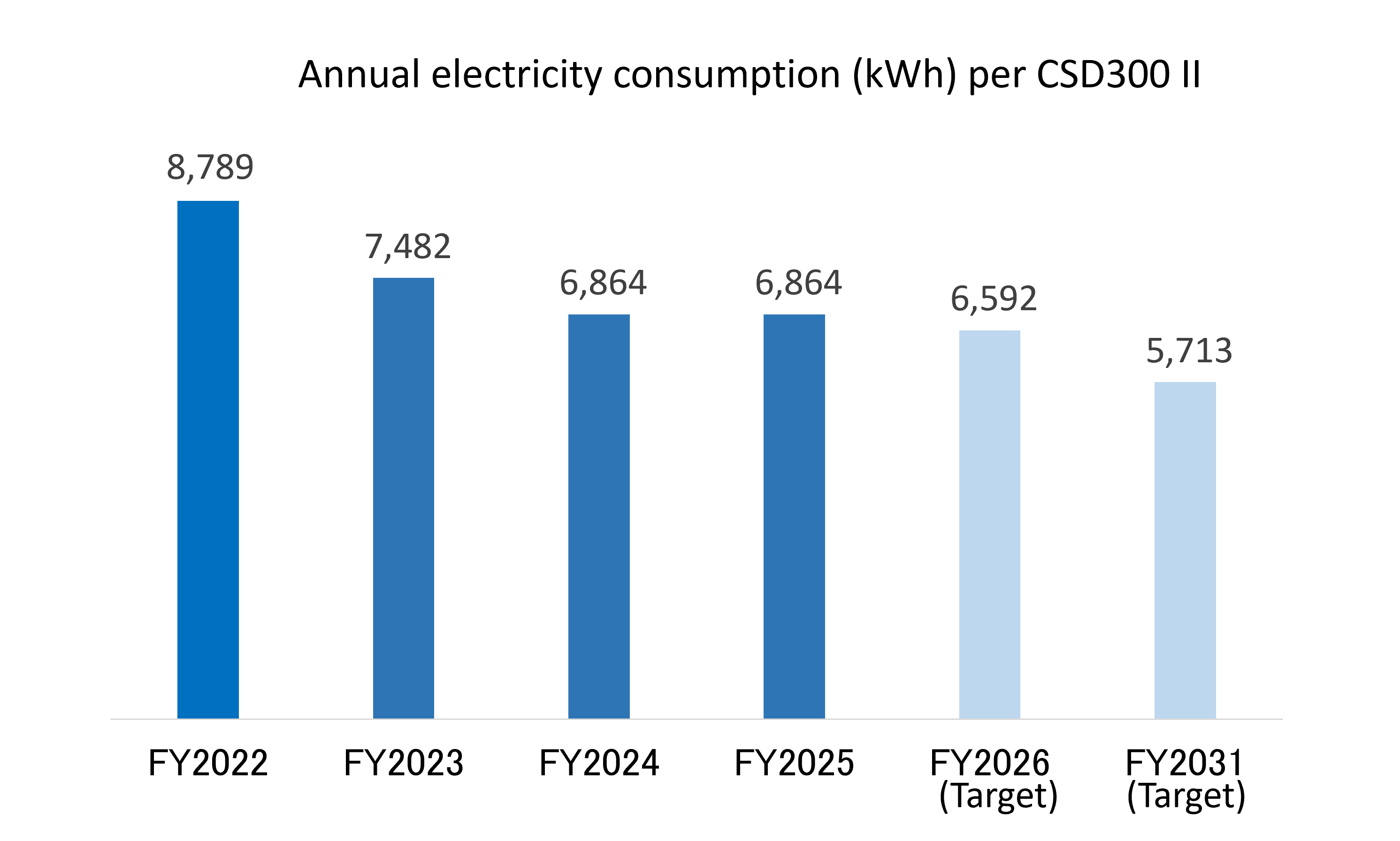

We are working to reduce power consumption of our products such as the CSD300II, a front facing twin spindle lathe. Efforts are being made to reduce waste (hydraulic standby control, air saving), shorten warm-up time through thermal displacement compensation, and promote visualization (energy saving screen).

Develop environmental contribution products

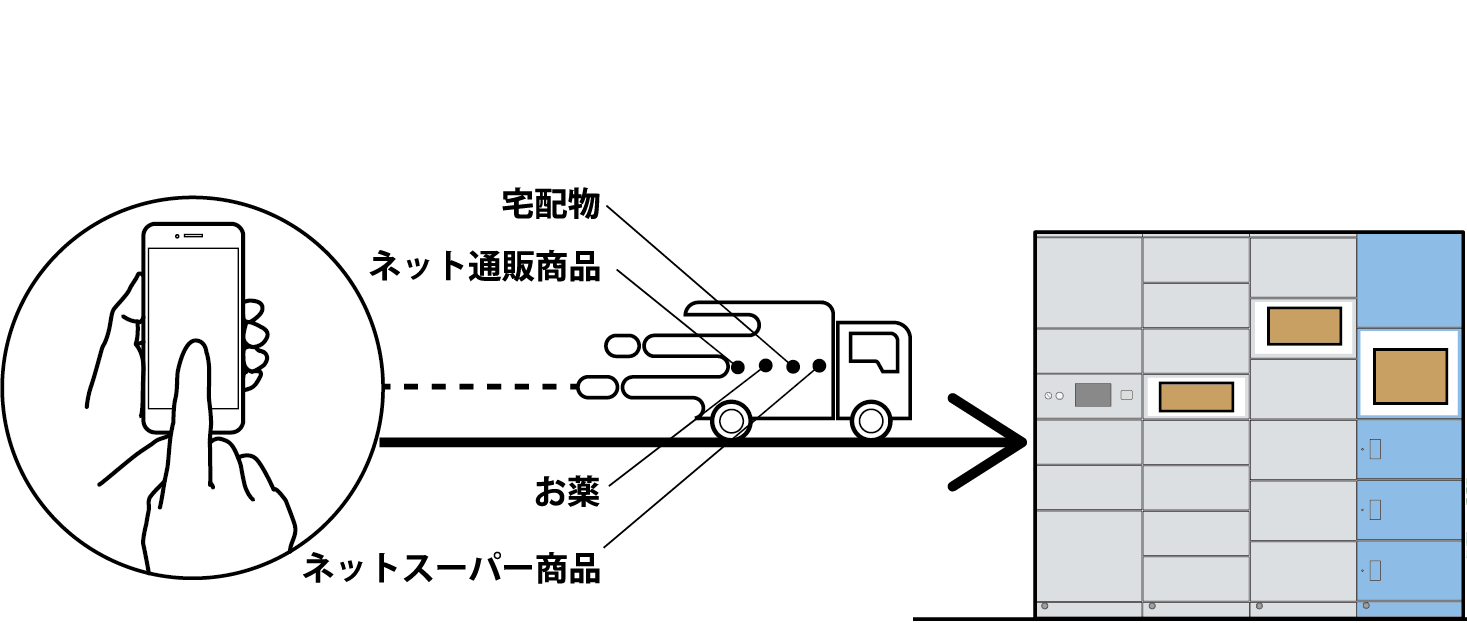

The public stocker system, Quist, is a delivery locker that enables the consolidation of delivery locations as a solution to the last mile problem.。

The "last mile problem" refers to the the issue of inefficiencies or increased costs that can occur in the final section of logistics, from delivering goods to the customer, who is the final destination.

It is possible to solve the following problems and contribute to reducing CO2 by consolidating delivery locations.

- ・Redelivery of items

- ・Idling and slow driving due to worsening traffic congestion in urban areas

The electronics 3D printer, "FPM-Trinity", is a machine that combines both circuit formation by printing and ultra-low temperature parts placement. This revolutionary process significantly reduces the amount of liquid and waste materials used in manufacturing electronic circuit boards.

The waste-sorting robot, R-PLUS, is a machine that automates the manual sorting process for recycling industrial waste with AI-based detection technology and picking hands. This unit contributes to improved and stabilized recycling efficiency through automation of waste sorting.

Participation in Model Project for Promoting Decarbonization Throughout the Value Chain Initiative From the Ministry of the Environment in fiscal 2024

The Ministry of the Environment of Japan implemented a project to support efforts to promote decarbonization management through collaboration among multiple companies and to create an advanced model for reducing emissions throughout the value chain.

We participated in this project together with three suppliers and one group company that manufactures overseas, in order to work towards achieving carbon neutrality.

We received interest from government agencies and manufacturing organizations regarding the knowledge gained from this project and supplier support methods, and were able to expand our scope of activities through seminars and other means.

Going forward, we will expand this project to more suppliers and work to reduce CO₂ emissions across the entire value chain, striving to achieve the Fuji Group's long-term environmental goals as soon as possible.

Action plans

- Raise employee awareness for carbon neutrality and incorporate it into departmental policies

- Provide environmental education (new managers, new employees)

- Conduct study sessions for carbon neutrality for the supply chain

- Calculate primary data in cooperation with suppliers and group companies

- Present at the industry-based practical seminars for reducing greenhouse gas emission hosted in Gifu, Japan

- Present at a seminar for the Green Value Chain Promotion Network hosted by the Ministry of the Environment for Japan

- Present at the seminar for policy trends and case studies for reducing greenhouse gas emissions held by the Japan Electrical Manufacturers' Association (JEMA)

- Register as a goal setting member of the Green Value Chain Promotion Network (jointly operated by the Japanese Ministry of the Environment; the Ministry of Economy, Trade and Industry; and the Ministry of Agriculture, Forestry and Fisheries).

Briefing on carbon neutrality for executive officers

Meetings with partner companies

Industry-based practical seminars

for reducing greenhouse gas emission

Collaboration with suppliers

Study session implementation status

| Date | Session | Companies | Participants |

|---|---|---|---|

| 日付Jan. 2023 | 内容

Carbon neutral information session |

参加社数(社)13 | 参加人数(名)50 |

| 日付Apr. 2023 | 内容

Carbon neutral information session Briefing on subsidies by financial institutions |

参加社数(社)17 | 参加人数(名)37 |

| 日付Mar. 2024 | 内容

"Model Project for Promoting Decarbonization Throughout the Value Chain Initiative" from the Ministry of the Environment report meeting |

参加社数(社)129 | 参加人数(名)147 |