Sustainability

Environmental Management Data

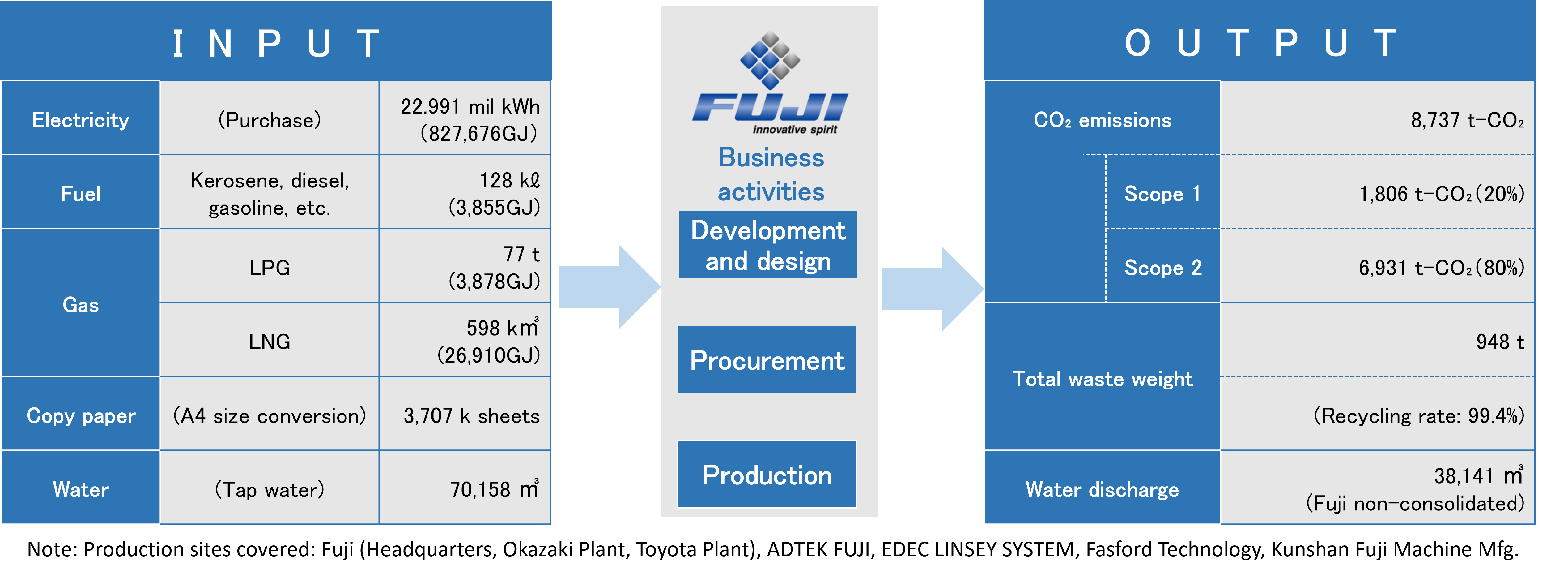

Environmental impact framework (fiscal 2025)

We strive to reduce our environmental impact by understanding our resource inputs and waste outputs at Fuji Group production sites.

Environmental Management Data

The scope of data management was expanded to include Fuji Group production sites from fiscal 2023. We will work on environmental data management for the entire Fuji Group.

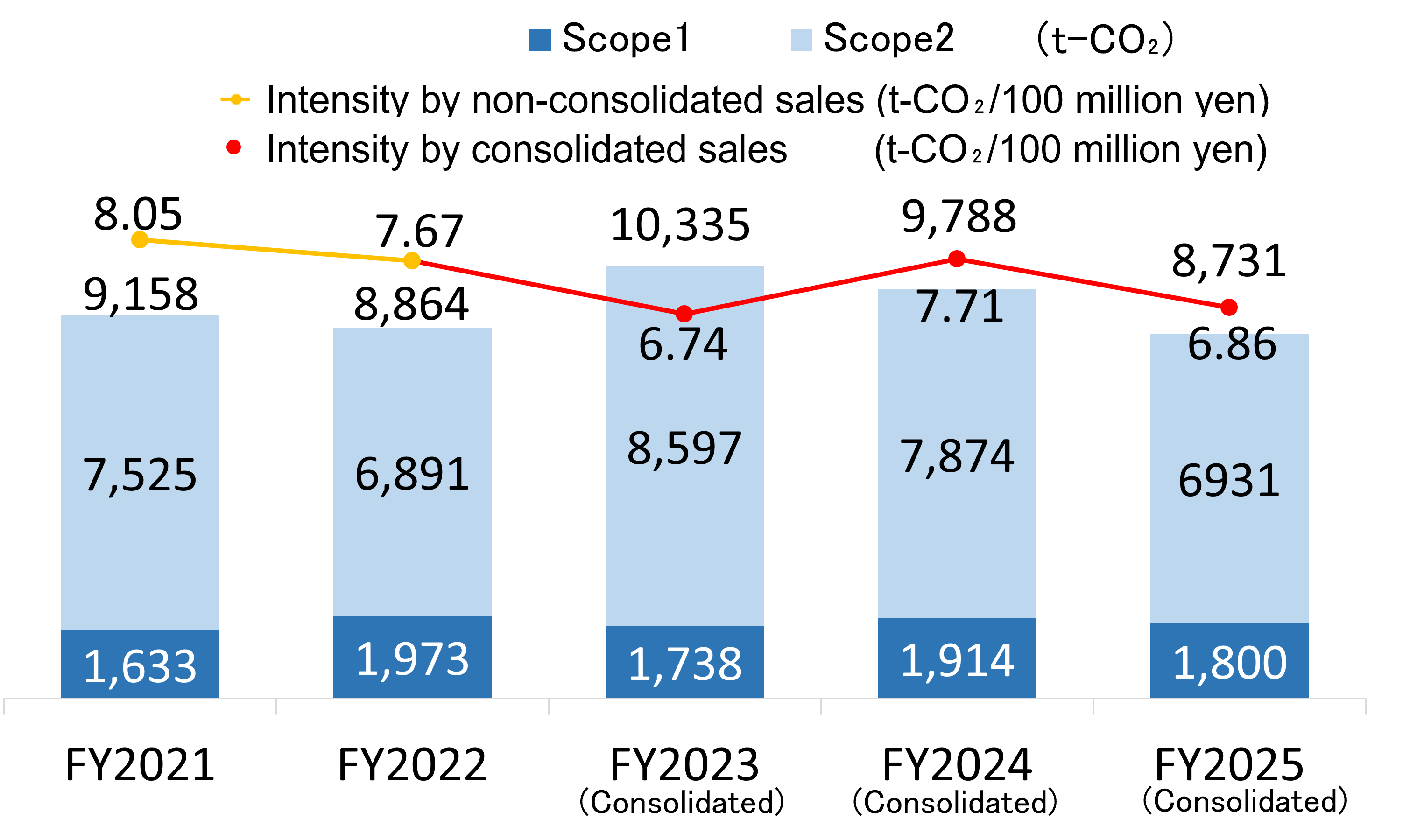

CO₂ emissions and intensity by sales

In addition to energy-saving activities by employees, we are striving to reduce CO₂ emissions through installing energy-saving equipment, purchasing CO₂-free electricity, and managing room temperatures.

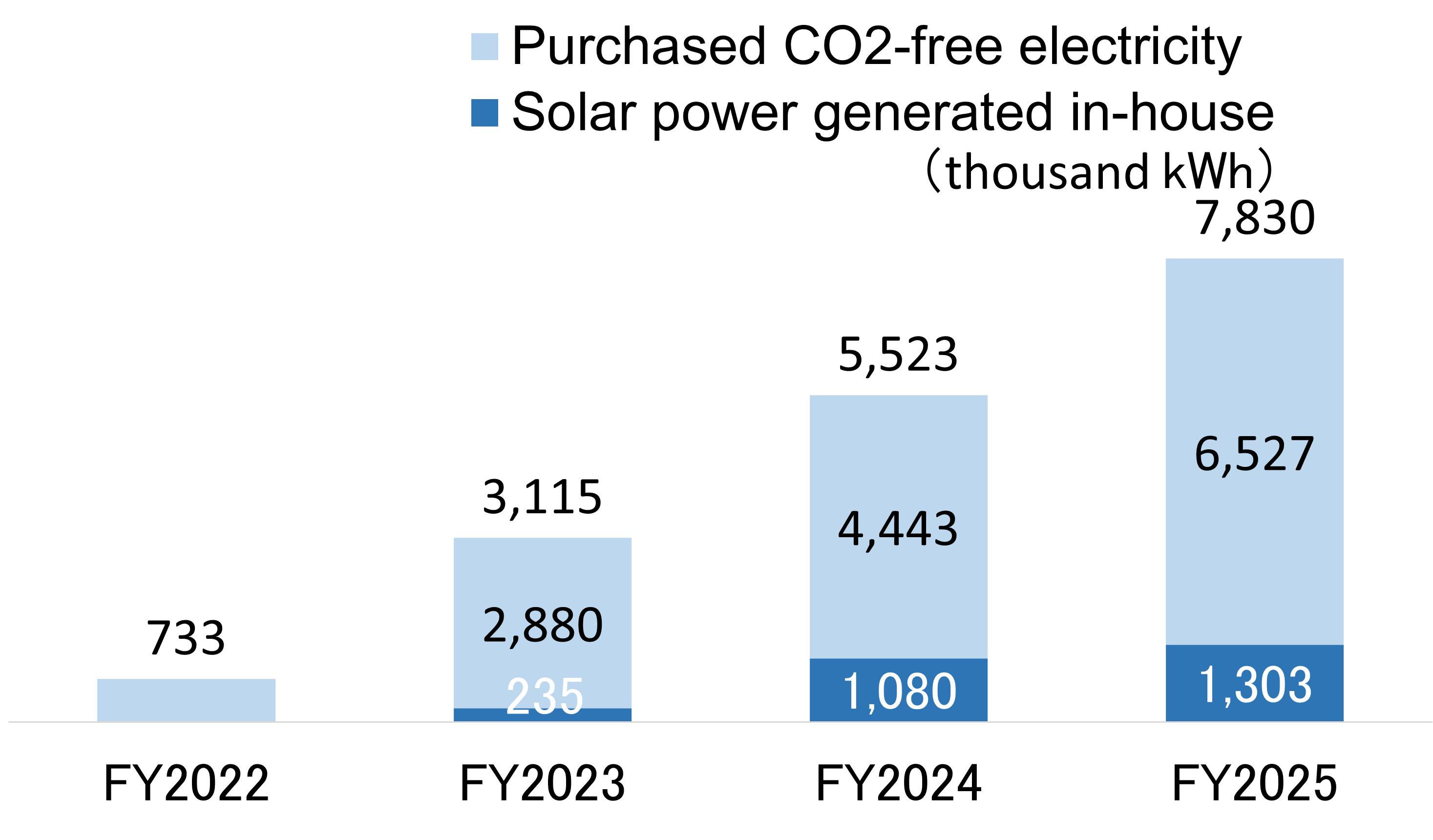

Amount of renewable energies introduced

In addition to Fuji Toyota Plant's part processing factory, EDEC LINSEY SYSTEM, and Fasford Technology, solar power generation systems have begun operating in some buildings at Fuji Okazaki Plant from September 2024.

Fuji Group is gradually increasing the ratio of CO₂-free electricity purchased to reduce CO₂ emissions.

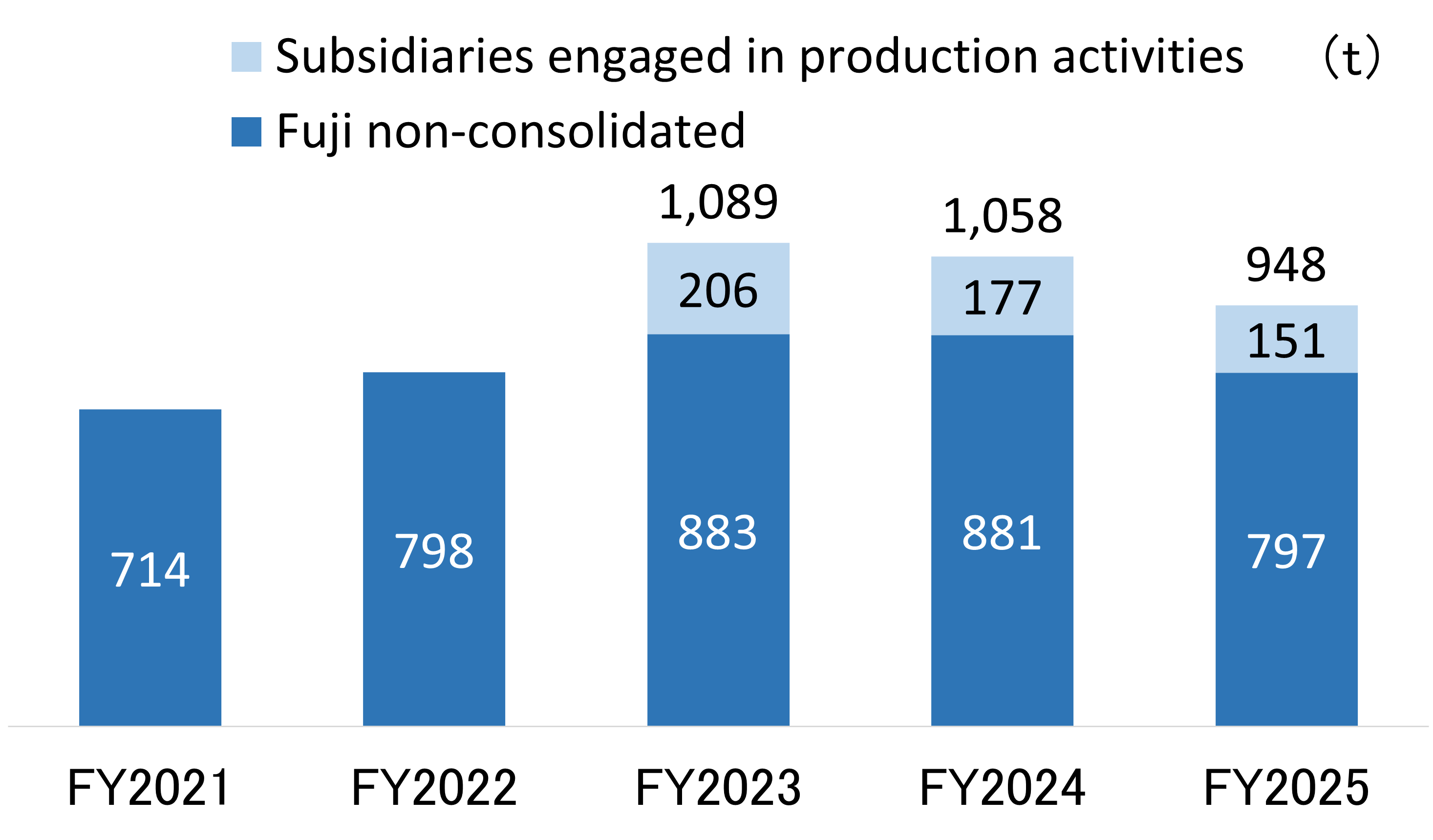

Total waste volume

We will be more committed to waste reduction and recycling of used resources in order to contribute to the establishment of a recycling-oriented society.

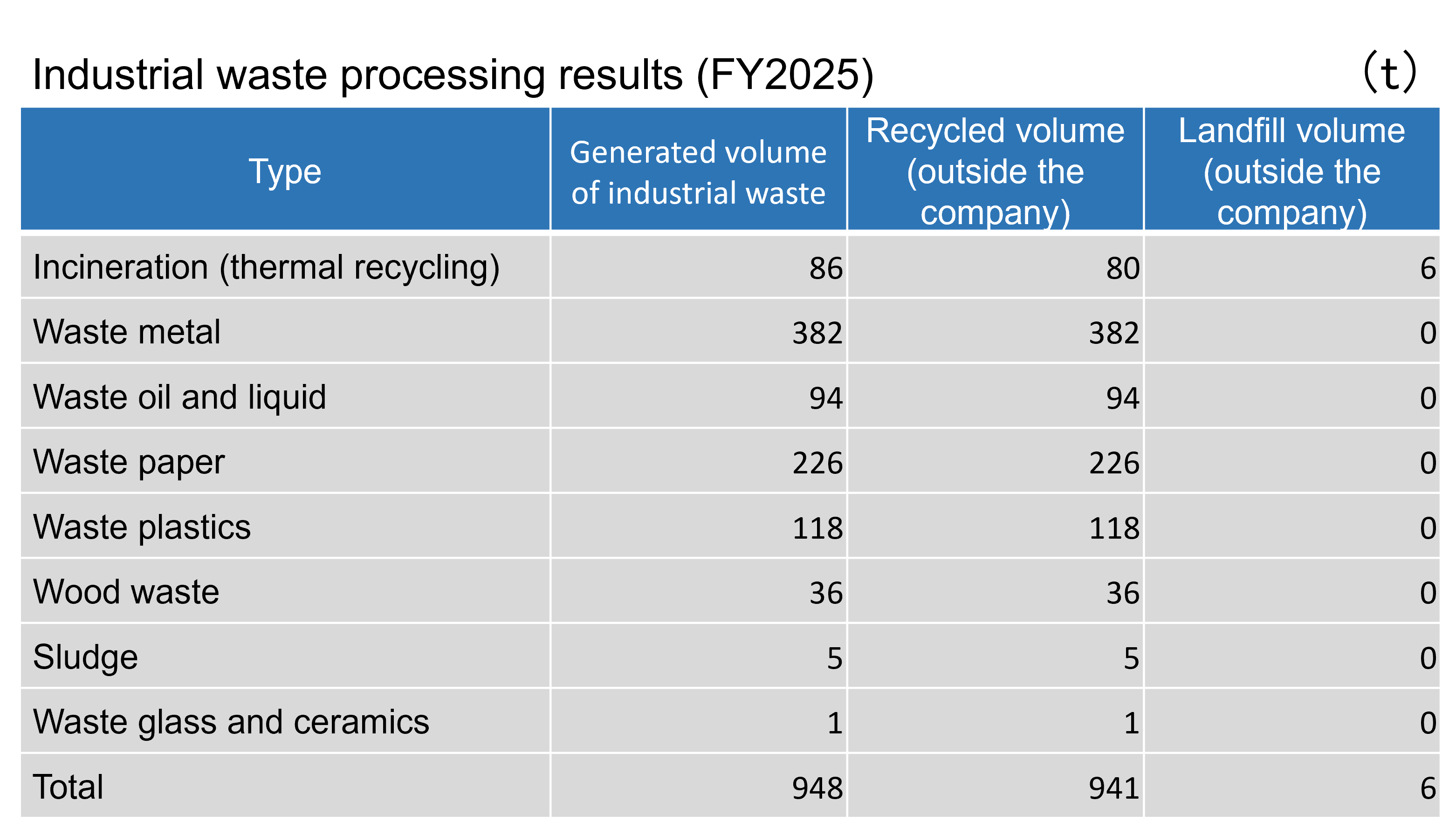

Waste processing results

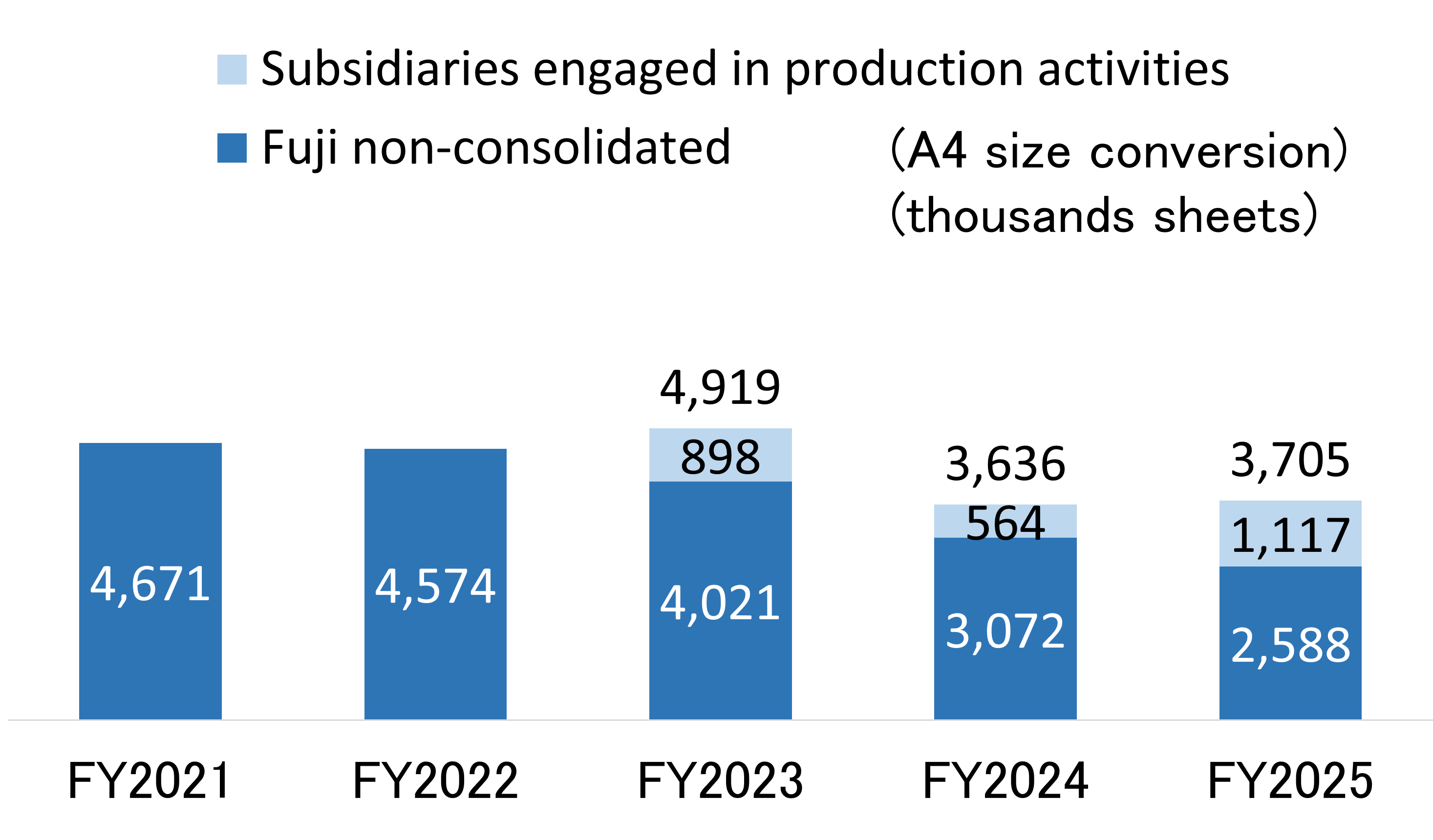

Amount of copy paper purchased

We are making company-wide efforts to reduce use of paper by eliminating paper materials, shifting to workflow systems, promoting a paperless environment on the production floor by introducing production systems, and switching to electronic files for documents submitted to customers, which leads to improved work efficiency and digitalization.

Water Risk Assessment at Production Sites

We conducted a water risk assessment of our production sites using the Aqueduct Water Risk Atlas provided by the World Resources Institute (WRI).According to the fiscal 2024 assessment, our site in China was identified as being located in a region with a high level of overall water risk.

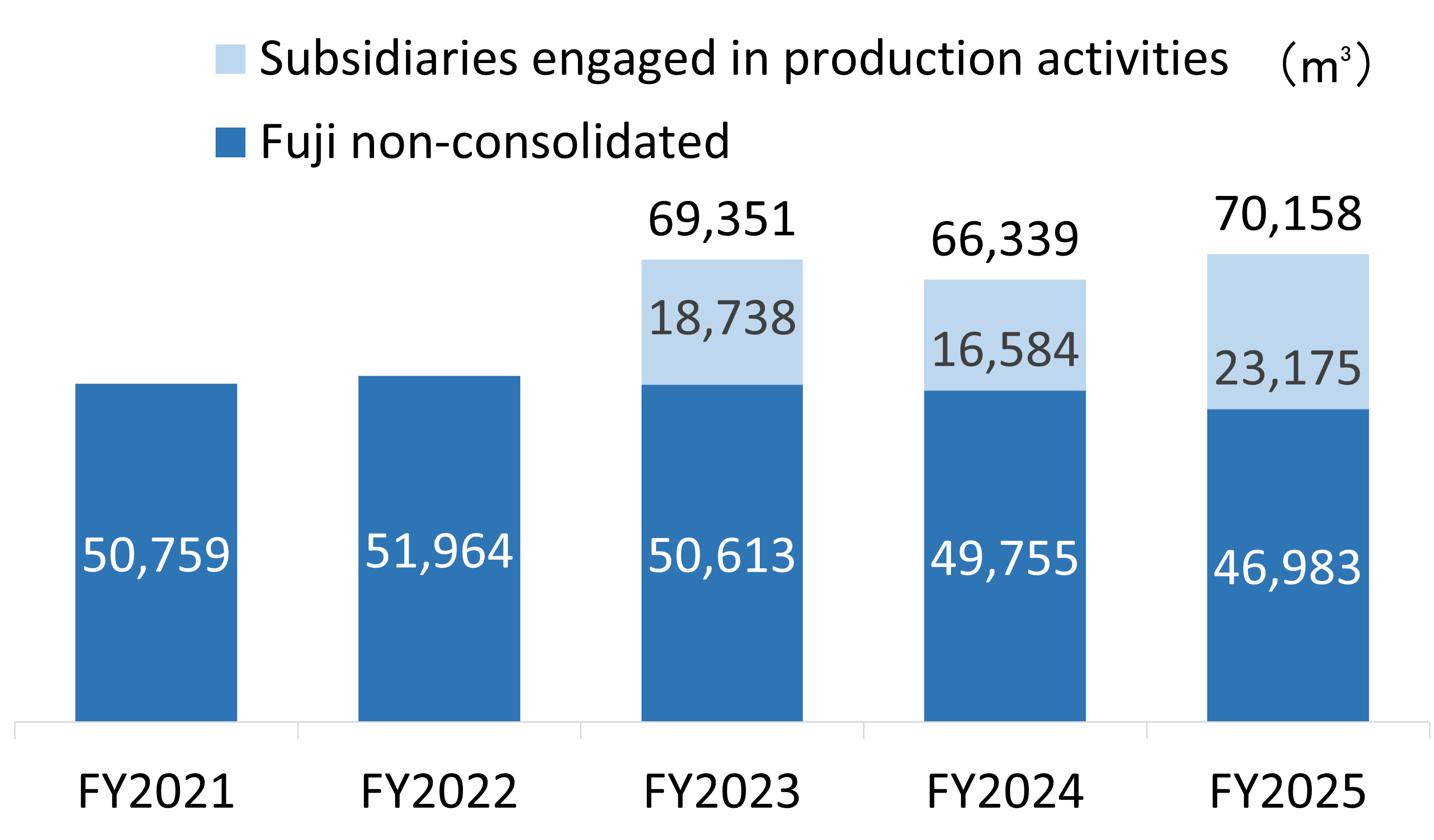

We strive to conserve water at the water source by managing the volume of water purchased. We purchase tap water from public water facilities and use it mostly for daily activity purposes.

Response to water pollution

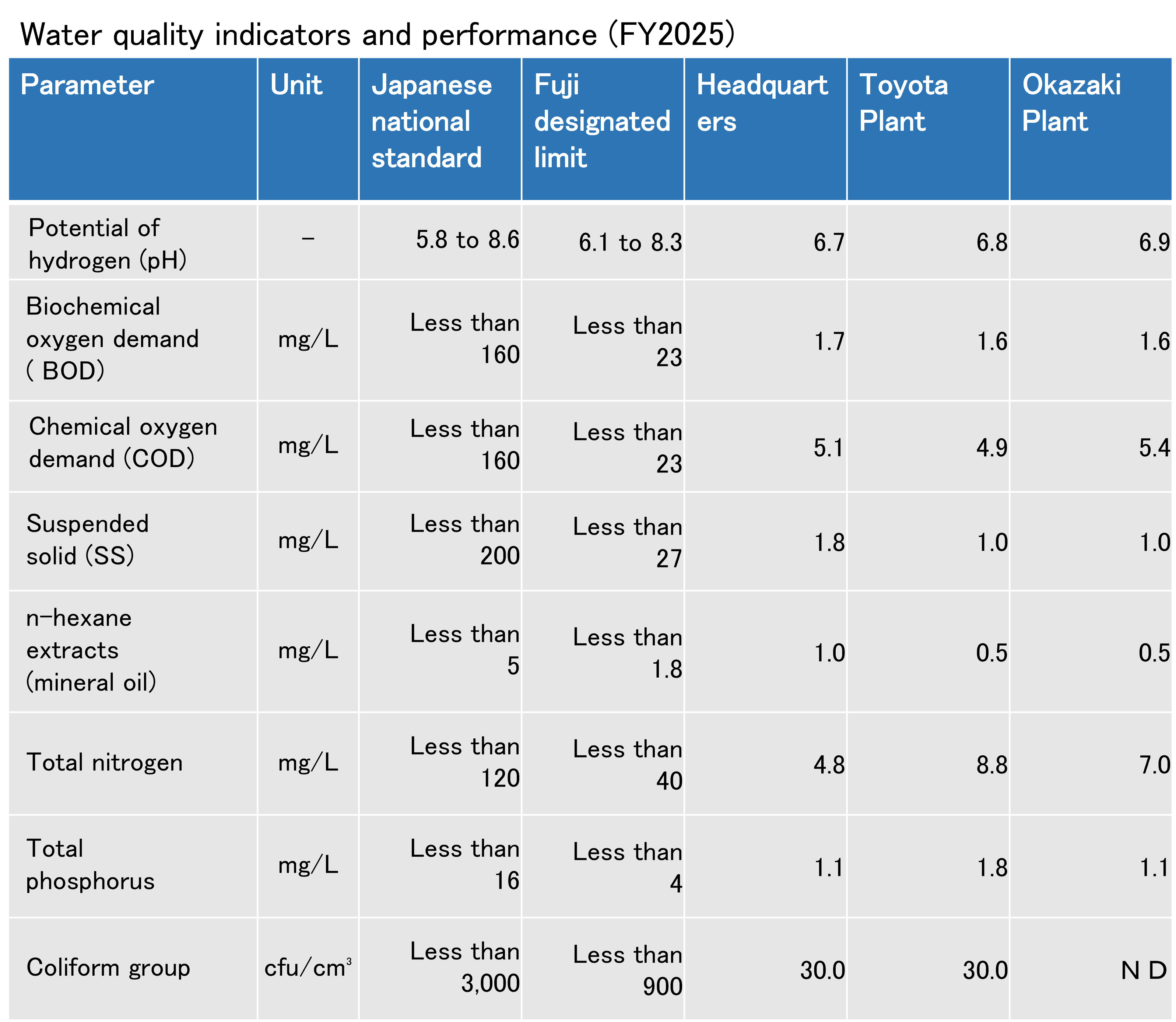

In consideration of aquatic ecosystems, we have established our own management standards, which are more stringent than Japanese regulatory standards, to control wastewater discharged from our plants. Our water quality inspection in fiscal 2025 showed we have not exceeded our designated limits for all categories. We will continue to manage the discharge of wastewater to reduce the environmental impact on local communities.

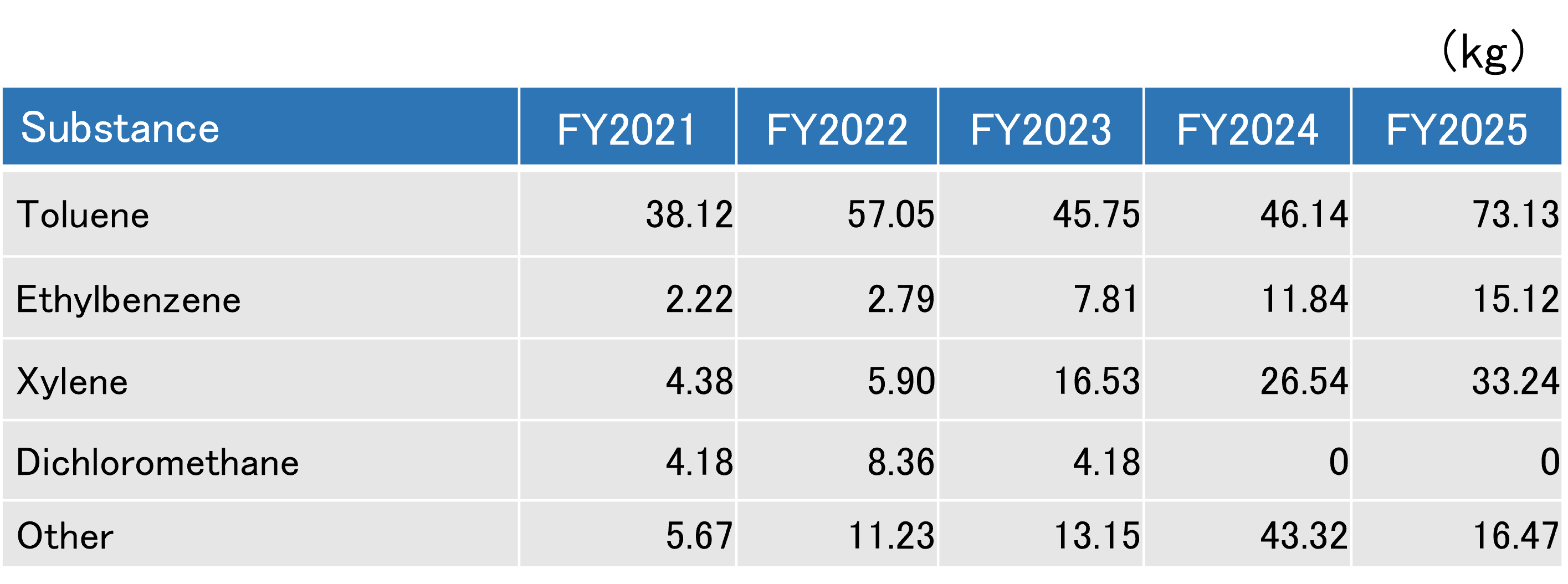

Chemicals used

We have created a chemical substance handling and management guideline based on laws and regulations, etc., and are working to reduce health and safety risks and environmental impact by properly managing the handling of chemical substances used within the company.

The scope of the environmental management data includes Fuji (headquarters, Okazaki Plant, Toyota Plant), ADTEK FUJI, EDEC LINSEY SYSTEM, Fasford Technology, and Kunshan Fuji Machine Mfg., while the scope of the data for water pollution control and chemicals used includes Fuji (headquarters, Okazaki Plant, Toyota Plant).